Contents

INTRODUCTION

Chapter 1. TECHNOLOGICAL PROTECTION

Watermarks

Methods of imitation of watermarks

Security threads

Imitation of security threads

Security fibers

Imitation of security fibers

Optically variable paints

Imitation of optically variable paints

Holographic protection

Paper composition and its optical properties

Imitation of paper properties

Chapter 2. PHYSICOCHEMICAL PROTECTION

Luminescent protection

Imitation of luminescent protection

Infrared protection

Attempts to imitate infrared protection

Magnetic protection

Imitation of magnetic protection

Other types of protection

Chapter 3. PRINTING SECURITY

Classical printing: features of the main printing methods

Letterpress printing

Flat printing

Gravure printing

Screen printing

Special types of printing

Other methods of printing security

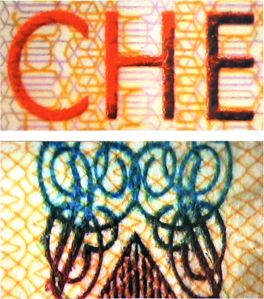

Microprinting

Attempts to imitate microprinting

Combined images

Imitation of combined images

Latent images

Attempts to imitate latent images

Imitations of printing security methods

INTRODUCTION

In everyday life, each person constantly has to deal with various documents. For most of us, the word «document» evokes very specific associations: it is some kind of «official» paper with text, signatures, seals and other details — for example, a passport. In fact, much more often we encounter other types of documents, which, although they do not quite correspond to this idea, play no less a role in our lives.

So, when we make purchases, we deal with money, in particular, with paper money — Russian or foreign. When we buy tobacco or alcohol — we see excise (special) stamps on the products. When exchanging money at an exchange office — we present a passport or other identity document. Drivers of motor vehicles, among other things, when communicating with police officers present registration certificates, coupons and other documents. Not to mention bills of exchange, shares and other securities, which we increasingly encounter every day.

At the same time, usually unconsciously, each of us decides for himself the problem — whether the document he holds in his hands is genuine or counterfeit. And for this, willingly or unwillingly, a person has to find out — to what extent does this document correspond to his idea of authenticity: what in it has the characteristics of the real thing, and what may indicate a fake.

How do we resolve this issue for ourselves?

The fact is that each document is provided with a certain set of tools, usually called protection.

Document protection is a set of features implemented using visual characteristics and special technologies and allowing to unambiguously establish the authenticity of the document.

In this case, technology is usually understood as a set of processes, equipment and materials that ensure a specific effect, observed visually or with the use of special devices.

In general, the purpose of protection is to create a set of features designed to identify a document as genuine.

In this regard, it is necessary to clearly distinguish between the means of protection that determine the authenticity of a document: a) for the consumer, b) for a specialist.

For the consumer, the most important features are those that allow the authenticity of a document to be determined quickly, easily and without the use of special means (devices, observation conditions and methods).

An example of such protection is a watermark on paper. On money, for example, it is visible when held up to the light — just hold the banknote up to the light (Fig. 1).

Fig. 1. Watermark on paper of a 100-ruble banknote

issued in 1997.

A specialist needs characteristics that ensure — with general external similarity — confirmation of authenticity under special conditions: the presence of special devices and special knowledge.

An example of such protection is infrared protection of special brands. To determine such protection, special devices are needed; if they are available, the observed picture (Fig. 2) serves as one of the reliable evidences of the authenticity of the document for the specialist.

Fig. 2. Infrared protection of special brands

«Strong alcoholic beverages».

In any case, document protection is a set of means, and the presence of one or more of them separately cannot serve as a basis for deciding the question of authenticity. Only the entire set of protective means can confirm the authenticity of the document.

In addition, protection — as the name suggests — is designed to complicate or make it impossible to falsify the document.

Usually, when talking about protection, it is customary to distinguish three of its types: technological, physical-chemical and printing. Although this division is quite arbitrary, most means of protection, as a rule, fit well into this classification.

Below is a description of all the listed types with their varieties, as well as known from practice methods of counterfeiting. Here it is appropriate to immediately make a reservation: in the future, we will talk mainly about the imitation of means of protection, and only in some cases — about their reproduction.

Under imitation refers to techniques that ensure that counterfeits produce effects similar to genuine documents (perceived visually or with the help of devices), but achieved using other (non-original) technologies, that is, methods different from those used to implement security features in genuine documents.

In contrast to imitation, reproduction— this is a repetition in one way or another of the original security technologies. Usually in practice such counterfeits are classified as “super”. This is due to the fact that the security features in genuine documents are manufactured using complex, often unique technologies, the reproduction of which requires special equipment, materials and special knowledge.

TECHNOLOGICAL PROTECTION

WATERMARKS Methods of imitation of watermarks

SECURITY THREADS Imitation of security threads

SECURITY FIBERS Imitation of security fibers

OPTICALLY VARIABLE PAINTS Imitations of optically variable inks

HOLOGRAPHIC SECURITY

PAPER COMPOSITION AND ITS OPTICAL PROPERTIES Imitation of paper properties

Chapter 1

Technological security is usually called a set of features discovered during the study of the materials that make up a document, and, above all, its substrate (most often, this is paper).

This type of security includes:

- paper watermarks; security threads (stripes);

- security fibers;

- paper composition and its optical properties; optical properties of paints; holographic images.

WATERMARKS

Watermarks are images formed during the production of paper due to local changes in its thickness and visible when held up to the light. This is the most common and reliable type of paper protection. At the same time, this is a rather complex type of protection, since its production requires the presence of special technological equipment (papermaking machine).

Watermarks obtained during the production of paper are usually called natural (true). Such watermarks are characterized by a change in the thickness of the paper in the places where the image is located.

All currently known methods of simulating watermarks are based on various methods of changing the optical density of the finished paper.

Depending on the number of visually observable gradations (tones, densities) that differ from the density (background) of the paper, watermarks are usually divided into:

- monotone (light or dark);

- two-tone;

- multi-tone (halftone);

- combined, combining elements of the previous types.

Single-tone watermarks are images that are visible when held up to the light, either dark or light in relation to the background of the paper. A typical example of a single-tone (dark) watermark is a watermark on travel documents (railway tickets). A light single-tone watermark can be seen, for example, on the Ukrainian hryvnia issued in 1992 (Fig. 3).

Fig. 3. This is what single-tone watermarks look like: a is dark, b is light.

Two-tone watermarks contain both lighter and darker images in relation to the paper background. They are found on banknotes (denomination symbols on Russian rubles, Fig. 4), and on special stamps (Strong alcoholic drinks, Fig. 5), and on identity documents (USSR passport, Fig. 6).

Fig. 4. Two-tone watermark on the paper of the 10-ruble banknotes issued in 1997.

Fig. 5. Two-tone watermark on the paper

of special stamps «Strong alcoholic drinks».

Fig. 6. Two-tone watermark on the paper

of the passport of a citizen of the USSR.

The watermarks shown in Figures 5 and 6, by the nature of their arrangement, are classified as field (general) marks, that is, their design (pattern) is repeated many times over the entire observed field.

In addition, there are local watermarks, the image of which is located in a specific place on the banknote or document page.

As a rule, local watermarks are multi-tone — their images contain smooth changes in density. They are often called halftone or portrait, since the most common such marks are in the form of portraits of personalities — persons depicted on banknotes (German stamps, Fig. 7).

Fig. 7. Halftone (portrait) watermark

on a banknote of 200 German marks.

This illustration also shows a combined watermark, combining multi- and single-tone (portrait and denomination designation).

A type of local watermark is a repeating (strip) watermark. It is a repeating — usually vertical — identical images. It is usually found in the form of portraits on banknotes (Swedish and Norwegian crowns).

Methods of imitation of watermarks

Practice shows that most often watermarks are imitated in the following ways:

-

overprinting (drawing);

-

impregnation with fatty substances; embossing (pressing);

-

mechanical scraping.

The most common method is to imitate a watermark by overprinting (drawing). This method is usually used to imitate single-tone dark, two-tone and multi-tone signs. Overprinting is usually done with a coloring agent that matches the shade of the paper used (usually white paint).

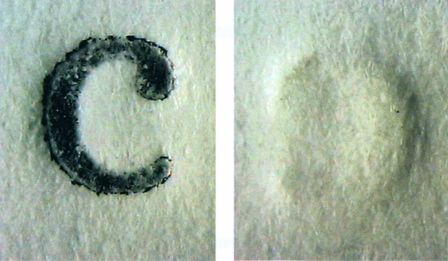

Such imitation is usually most easily detected under ultraviolet rays (UVR). When the document is illuminated with UV rays, the overprinted image appears dark against a lighter background of the paper (Fig. 8, a). Watermarks imitated in this way usually have clear boundaries when viewed against the light (Fig. 8, b), since most often the paint is applied from a letterpress (cliché) or flat printing form, less often — by drawing with a pen or brush. When imitating a watermark from a rasterized printing form, it is possible to transfer halftones of the image of a multi-tone watermark — for example, a portrait (Fig. 9).

In addition, the presence of an overprint can be determined in diffuse and oblique lighting, and the image of the simulated watermark will differ from the background of the paper by the nature of the reflection — gloss (Fig. 10).

Fig. 8. Watermark simulated by an overprint from a line form:

a — under ultraviolet rays;

b — against the light.

Fig. 9. Imitation of a halftone watermark,

made from a raster form:

a — against light; b — in UV light.

Fig. 10. View of the overprinted «watermark»

in oblique light.

Impregnation is usually used to imitate light, single-tone watermarks. Wax-like substances or oil-containing compositions are used for such imitation. In this case, the image of the watermark is applied to the substrate (paper), either from some printing form or by hand, using a pen-type instrument. Imitations made in this way are characterized by a somewhat «blurred» picture, observed when held up to the light. The longer a document with such a «watermark» is in circulation, the more the image blurs. Nowadays, counterfeits of this type are becoming less common.

Watermarks are often imitated by embossing. This involves local compaction of the paper in places corresponding to the light areas of the watermark. As a rule, such imitations have little contrast to the background of the paper when viewed in transmitted light. However, they are usually very visible in oblique lighting. The characteristic features of a watermark imitated by embossing are shown in Fig. 11.

Fig. 11. This is what watermarks imitated by embossing look like:

a — when viewed against the light;

b — in oblique lighting.

A rather unusual and rare method of simulating watermarks by scraping is the method based on mechanically changing (reducing) the thickness of the paper layer. This method is quite successful in simulating light, single-tone watermarks. It is more difficult to obtain halftone watermarks by scraping. This requires manually removing part of the paper layer to different depths using a cutting tool (knife, scalpel) or an abrasive material — fine sandpaper, a hard eraser.

Depending on the print run and the artist's skills, such a counterfeit can be done either simply by hand or with the help of a template (stencil). An example of imitation of a watermark using this method is shown in Fig. 12. The figure shows that when viewed against the light, such a «watermark» looks quite rough, and in oblique light, local violations of the surface finish of the paper are clearly visible.

Fig. 12. Imitation of a watermark by mechanical scraping:

a — view against the light; b — view in oblique lighting.

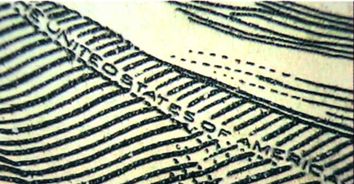

PROTECTIVE THREADS

A security thread is a narrow (1-2 mm wide) strip of polymer material embedded in paper during its production. When examining a document, security threads are detected in transmitted, reflected, diffused, and oblique lighting.

Security threads vary widely in appearance, but there are two main types:

-

threads that are completely hidden in the paper (for simplicity, we will call them hidden hereinafter);

-

diving (fenestrated) threads, fragmentarily protruding onto the surface of one side of the paper (usually in the form of a dotted line of several equal segments).

Hidden threads are visible only when held up to the light. They, in turn, are divided into the following options:

-

metallized solid — are observed as an opaque strip (Fig. 13);

-

metallized with text — in the form of an opaque strip with transparent (light) letters and numbers;

-

transparent with text — a translucent strip with opaque (dark) symbols or images (Fig. 14).

Metallized threads can also have magnetic properties. Transparent threads sometimes luminesce in some color when observed under ultraviolet rays. These properties can manifest themselves both along the entire length of the thread and locally (Fig. 15).

Fig. 13. Solid metallized security thread

(1000 Armenian drams).

Fig. 14. Transparent security thread with text

and images ($50).

Fig. 15. Luminescence of security threads:

a — along the entire length (20 US dollars);

b — local (10 rubles).

The luminescent threads can be observed in transmitted and reflected light. As a rule, they are metallized, so in reflected light on one side of the document the thread appears as a dotted line of shiny segments of equal length, and when held up to the light such a thread appears as a continuous strip.

According to their design, diving threads are divided into the following types:

-

solid — no text or images are visible when held up to the light (Fig. 16);

-

with transparent text (Fig. 17);

-

with a holographic effect, that is, having a «rainbow» coating (Fig. 18).

Fig. 16. Translucent view of a solid diving thread (20 British pounds).

Bands with different optical density are visible.

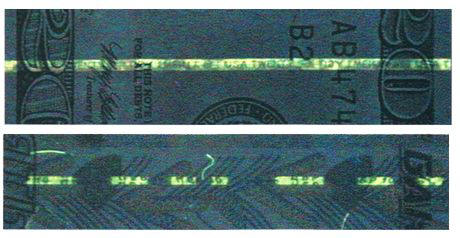

Fig. 17. Diving thread with transparent text (100 German marks):

a — translucent view; b — a section of thread with an image

applied on top of it.

There are also diving threads that luminesce in UV rays.

It should be noted that when examining in transmitted light, local changes in the optical density of the paper in the form of dark stripes perpendicular to the thread are detected in the area of the diving thread, and these stripes are located between the sections of the thread that come to the surface (Fig. 16).

It is also necessary to keep in mind the fact that the images on the document, regardless of the method of application, are located on top of the diving thread (Fig. 17b).

In oblique light, in areas where security threads of all types are located, a local thickening of the paper is observed, which looks like a relief strip (Fig. 19).

Fig. 18. Holographic effect on the thread

(CITICORP traveler's checks).

Fig. 19. Security thread in oblique light.

Imitation of security threads

There are four main methods of imitation of security threads:

-

overprinting;

-

finishing;

-

sticker;

-

pasting.

Various combinations of these methods are also possible.

Overprinting is most often used to imitate hidden threads. The following options are possible.

The simplest method involves printing the text (image) on the thread in white paint on one of the outer sides of the document or on the inner side of one of the sheets (for documents glued together from two sheets). In this case, unlike genuine documents, the boundaries of the thread itself are not visible in transmitted light, and in oblique light a relief overprinted image is visible. In UV rays, such overprinting usually appears as a dark image on a light background (Fig. 20).

Fig. 20. Imitation of a hidden security thread by overprinting the text:

a — in the light; b — in oblique light; c — in UV light.

To imitate a solid opaque thread, overprint with white paint in the form of a narrow strip.

The appearance of such imitation under various conditions is shown in Fig. 21.

Fig. 21. Imitation of a solid hidden thread:

a — in the light; b — in UV light.

Fig. 22. On the imitated thread, the text is visible through the translucent paint.

Often, the imitation of a thread with text is done in two stages. First, the text (image) is applied with dark paint, and then a strip of white or translucent paint is printed on top. In this case, the text is often visible through the paint in reflected light (Fig. 22).

There are imitation threads with text that combine the printing of text and the gluing of a strip of thin paper on top. In this case, the text is printed either on the surface of the document or on the paper strip (Fig. 23). The illustration clearly shows that in oblique lighting from the back, the glued strip of paper has clearly defined sharp boundaries and increased relief.

Fig. 23. Imitation of thread with a paper strip sticker:

a — against the light; b — in UV light.

In addition, in this same figure you can see a fairly common error made when imitating a thread with text. The fact is that on many security threads of this type the text (most often this is an alphanumeric designation of the denomination) is applied both in a straight, as well as in a mirror and inverted image. This is done to facilitate the readability of the text from any side. However, when imitating, this circumstance is not always paid attention to, and the text is only performed in a straight image.

A fairly common imitation of security threads is by gluing strips of polymer material (film) or thin paper with texts (images) applied to them between the sides of the document. An example of such imitation is shown in Fig. 24.

Fig. 24. Polymer strip with text,

pasted between thin sheets.

Fig. 25. Imitation of a diving thread by foil stamping.

The most difficult to imitate are diving threads. In order to obtain an external resemblance, such threads are imitated in various ways, the most common of which are the following:

-

sticking pieces of metallized foil;

-

embossing with printing foil (Fig. 25);

-

finishing with paint with a metal pigment «under silver» (Fig. 26).

In this case, transparent text can be applied in some way (for example, etched or scratched) on the metallizing layer of foil.

All these methods, however, allow to obtain the effect of a diving thread only in reflected light. When observed against the light, such imitations look like dotted lines. To achieve greater similarity, an opaque (semi-transparent) strip is additionally printed on the reverse side. In this case, however, it is rarely possible to achieve precise alignment of the imitating elements on the front and back sides of the document (Fig. 27).

Fig. 26. Imitation of a diving thread with silver paint.

Fig. 27. Misalignment of the translucent strip with the pieces of foil.

All of the listed types of imitations of security threads, as a rule, have significant differences from the genuine ones. They differ most significantly when observed in transmitted light (degree of transparency, configuration and dimensional characteristics of texts), ultraviolet rays (character of luminescence or its quenching) and oblique lighting (character of paper thickening at the location of the thread).

SECURITY FIBERS

Protective fibers are introduced into the paper mass during its production. They differ from the total mass of fibers that actually make up the paper by certain properties: color, the nature of luminescence under ultraviolet rays, and sometimes both.

The following types of protective fibers are commonly used:

-

colorless, luminescent in UV rays;

-

dyed (colored), not glowing in UV rays;

-

dyed, luminescent with «their» color (i.e. the color of luminescence is close to the visible color of the fibers) or some other.

Documents may contain security fibers of one or several types.

Figure 28 shows colored fibers used as a security feature in US dollar paper.

Figure 28. Colored security fibers

of US dollar banknotes.

Such fibers are usually located in the mass of the paper, but may partially (and sometimes completely) protrude onto its surface.

Colorless protective fibers are not visible under normal observation conditions — their appearance is practically no different from the general mass. Sometimes such fibers can have some shade, most often yellowish or greenish. When illuminated with ultraviolet rays, these fibers glow (Fig. 29).

Fig. 29. Luminescent protective fibers

paper of German brands.

Imitation of security fibers

Usually, when counterfeiting documents, security fibers are not given much attention. Imitation of colored fibers is performed by simple, accessible means, most often, in the following ways:

-

hand drawing;

-

overprinting;

-

sticker (rare).

In cases where fibers are imitated by drawing, their appearance depends on the tool used to create them. For example, a colored pencil produces a “loose” picture; the thickness of the stroke changes depending on the pressure applied, and traces of pressure are visible (Fig. 30). In “fibers” applied with a ballpoint pen (roller), a “drop” of paint is usually visible — the edges of the strokes are colored more intensely (Fig. 31).

Fig. 30. Imitation of a security fiber made with a colored pencil.

Fig. 31. Security fiber imitated with a roller.

Imitation of fibers made with overprinting (most often, this is offset printing) looks flat, the edges of the strokes can give the impression of being somewhat blurred (Fig. 32).

Fig. 32. Imitation of a protective fiber by overprinting (offset printing).

Sticking fibers is a rather labor-intensive process, so in practice such imitation is quite rare.

Since low-quality counterfeits are often made using various copying equipment (color copiers of different types), such counterfeits usually have an image of the fibers transferred from the original along with the document image. In these cases, the «fibers» have features characteristic of the copying method used. For example, Fig. 33 shows images of colored fibers obtained on a full-color electrophotographic apparatus.

Fig. 33. Images of fibers

reproduced during the copying process.

Fig. 34. Printed fibers on three different banknotes:

the shape and location are the same.

In cases where not one but several copies of a document are being studied — for example, a number of questionable banknotes — it is advisable to pay attention to the mutual arrangement and shape of the fibers. Often, one can encounter a situation where the same arrangement and configuration of fibers is observed on different banknotes (Fig. 34). This circumstance indicates either that the fibers are imitated by overprinting (and from the same printing plate), or that the same original was used for copying.

OPTICALLY VARIABLE PAINTS

Optically variable (variable) inks are quite widely used nowadays as a means of technological protection of documents. In practice they are usually called OVI (from Optically Variable Ink). The essence of this type of protection is the use of special inks of complex composition, which, depending on the angle of illumination and observation, can change their color in a certain range.

Typically, such paints are used to apply image fragments made by metallographic printing — banknote denominations, names of issuing institutions. Currently, OVI are used in a wide variety of document types — banknotes, visas and visa coupons, securities. Almost all modern currencies are provided with such protection.

Figs. 35 and 36 show security elements made with optically variable paint: the Bank of Russia emblem on the 500-ruble banknote issued in 1997 and the denomination on the 100-dollar banknote issued in 1996.

Fig. 35. The emblem of the Bank of Russia on the 500-ruble banknote, made by OVI:

a — when viewed from the front; b — when viewed at an acute angle.

Fig. 36. The denomination designation on the 100-dollar US banknote, made by OVI:

a — when viewed from the front; b — when viewed at an acute angle.

The types shown in the illustrations do not give a complete picture of the color change — only the extreme positions are shown here, and in reality the color changes smoothly, as the viewing angle (or lighting) changes.

Imitations of optically variable paints

The vast majority of known methods of imitation of OVI with varying degrees of similarity reproduce only the effect of metallic shine inherent in these paints. However, such imitations do not change the color, which makes it quite easy to recognize a fake.

A variety of methods are used to achieve the gloss effect. Thus, Fig. 37 shows an example of imitation of OVI by applying an additional layer of transparent substance (varnish) to the paint surface, containing a small amount of metallic pigment particles (powder). Here we see that the contours of the varnish layer do not coincide with the border of the painted strokes.

The following illustration (Fig. 38) shows an attempt at imitation by applying metal powder to the paint. In this case, it can be seen that some of the powder also gets onto the whitespace elements.

Fig. 37. Imitation of OVI with transparent varnish.

Fig. 38. Imitation of OVI with metal powder.

Fig. 39 shows a fragment of a drawing simulating OVI and made with paint, containing small shiny «flakes» of the mica type.

Fig. 39. Imitation of OVI with paint with shiny «flakes».

Fig. 40. Imitation of OVI using intaglio printing:

a — enlarged fragment of a stroke;

b, c — the same image from different angles.

In Fig. 40a it is evident that the paint contains metal pigment particles. The other two figures show the same image when viewed from the front and from an acute angle: as can be seen, there is no color change effect.

HOLOGRAPHIC PROTECTION

This type of protection is currently undoubtedly one of the most reliable due to the high technological nature of the process.

Holographic images used as protective means are made using various technologies. Without going into the details of these processes, we note that they all have in common a large volume of transmitted information and the complexity of production.

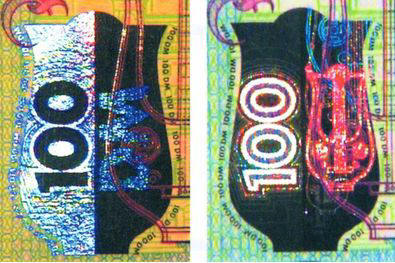

«Classic» holograms are images made on a special metallized foil with several «planes», that is, when observed from different angles, you can see different images, including three-dimensional ones.

A type of hologram is the so-called kinegram, which, when viewed from different angles, gives the effect of movement or change in the geometric dimensions of the depicted object.

Examples of holographic protection of various documents are shown in Fig. 41-44.

Fig. 41. Kinegram on a 200-mark banknote of Germany

(the effect of changing the size of the inscription «200» is observed).

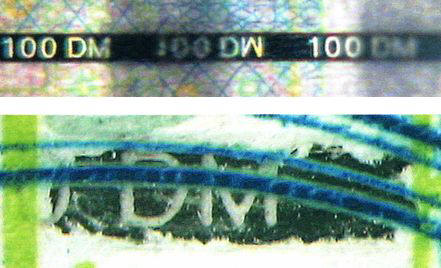

Fig. 42. Kinegram on a banknote of 100 German marks

(in the right part, different images are observed — the lira and the inscription «DM»).

In addition to visible images on holograms, they are additionally supplied with microprinting, which can only be seen through a microscope (Fig. 45), and, in some cases, hidden images, for the visualization of which special devices with laser sources and a carefully selected lighting angle are required.

Fig. 43. Holographic protection of the 20 pound banknote.

At different angles, either the denomination designation or the figure (medallion) «Britain» is visible.

Fig. 44. Holographic sticker on an excise stamp (Khabarovsk Krai)

— different «plans» of the image (tiger head, inscriptions, region code).

Fig. 45. Microtext on a holographic sticker (font size — 0.1 mm).

As can be seen from the illustrations provided, these are quite complex objects to reproduce. Therefore, as expected, any serious counterfeits of holographic protection are usually not encountered in practice.

PAPER COMPOSITION AND ITS OPTICAL PROPERTIES

Among the characteristics of paper used as technological protection, its optical properties are of primary interest (especially for a non-specialist), that is, what can be determined with the naked eye.

Such properties include, for example, tinting (dyeing of paper pulp, giving it a certain shade).

The pictures shown in Fig. 46 demonstrate various shades of paper of German mark banknotes. In addition, these illustrations also show another feature characterizing the paper of documents — the so-called marking from cloth and mesh. This indicator indicates the use of a certain paper-making machine — a device used for the production (casting) of paper.

These paper indicators can be used, along with other characteristics, to establish the authenticity of a document.

Fig. 46. Different shades of paper of German banknotes:

a — 100 marks; b — 200 marks.

Markings from cloth and mesh are visible.

Imitation of paper properties

Various methods are used to imitate the properties of paper of genuine documents. For example, to obtain paper that is «opaque» (non-luminescent) in UV rays (see also the section Physicochemical protection), various types of coatings (paints, varnishes) are applied to the surface of the paper in order to extinguish the natural luminescence of the paper.

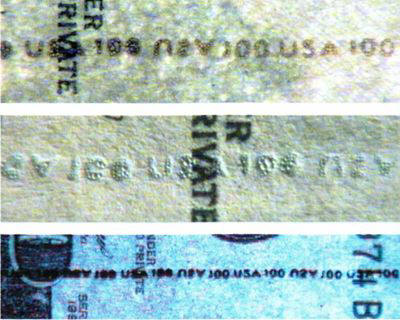

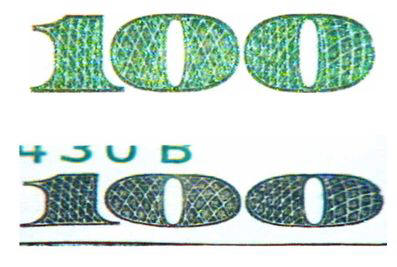

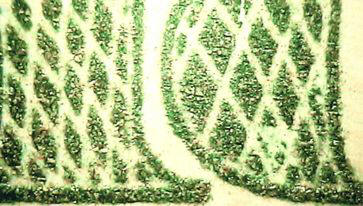

At the same time, even papers similar in composition and optical properties may differ in such a parameter as marking from the cloth and mesh. As an example, we will provide illustrations (Fig. 47), which show the difference, visible when held up to the light, between the paper of genuine $100 US banknotes issued in 1996 and the paper of counterfeit super-class banknotes.

Fig. 47. Differences in the marking from the cloth and mesh in the paper of genuine

and counterfeit $100 banknotes:

a — genuine banknote (square mesh cells);

b — fake (diamond-shaped cells, diagonal).

PHYSICAL AND CHEMICAL PROTECTION

LUMINESCENT PROTECTION Imitation of luminescent protection

INFRARED PROTECTION Attempts to imitate infrared protection

MAGNETIC PROTECTION Imitation of magnetic protection

OTHER TYPES OF PROTECTION

Chapter 2

When talking about the physical and chemical protection of a document, we usually mean the properties of its materials, detected in various areas of the spectrum. As a rule, these are various types of luminescence, absorption capacity and magnetic properties of coloring agents. We have already considered some of the types of physical and chemical protection in previous sections. They are often combined with other types of protection, usually with technological protection.

The most common types of physical and chemical protection are:

- luminescence (complete or fragmentary) of security threads;

- luminescence of security fibers; « luminescence of paints (colored or colorless);

- magnetic properties of paints and security threads;

- special coloring agents (so-called «marks»).

In addition, there are types of protection that are usually simply called chemical. Most often, this implies the presence of special substances (reagents) in the paper or paint, the purpose of which is to make it difficult or impossible to partially change the original content of the document (for example, by etching). When attempting this type of impact, the paper of the document or the paints used change their properties — usually, they acquire a different color.

Physical and chemical protection, unlike technological protection, is detected not visually, but with the help of special devices. These devices can be divided into two groups: visualizers and detectors (sensors). The first group allows you to visually observe the protection effect, for example, the glow of a protective element (fiber, thread, pattern) in ultraviolet rays. It can also be a picture of the absorption of infrared rays or magneto-optical visualization of the properties of the dye. Devices of the second group work on the «yes-no» principle, that is, they react to the presence of a protective feature, giving an audible or visual signal.

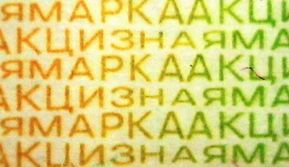

LUMINESCENT PROTECTION

This is, as a rule, the glow of security elements (fibers, threads, paints), excited by ultraviolet ray (UVR) sources in various ranges of this spectrum (see examples in Fig. 15, 29). In practice, sources with a radiation wavelength of 365 nm and 254 nm are most often encountered. Such devices can be made in the form of portable illuminators («flashlights») or built into stationary devices.

The glow is provided by the presence of special substances in the document materials, called luminophores. The range of such substances is very wide, they glow under UV in a variety of colors, but most often — blue, yellow, green and red.

It should be noted that so-called blankophores, or optical brighteners, are usually added to the composition of «consumer» papers — writing, printing — to make the papers whiter. This is done to make the papers whiter. Such papers, as a rule, have a bright white-blue glow in UV light.

In practice, the term «bank paper» is also used. It refers to special paper used to produce banknotes, securities and a number of other documents. Papers of this kind usually do not have pronounced luminescence in ultraviolet rays (sometimes they say «blind» in UV paper). Such properties of paper can also be attributed to technological protection, since they are determined by the composition of the paper.

An example of the luminescence pattern of a 200 German mark banknote under UV rays is shown in Fig. 48. The figure shows the glow of the protective fibers of the paper, one of the paints in the background security mesh and the paints of the serial numbers.

Fig. 48. Luminescence of a 200 German mark banknote under ultraviolet rays

Imitation of luminescent protection

Luminescent protection is used in a wide variety of documents. However, due to the widespread use of luminophores both in everyday life (for example, they are included in many detergents) and in production, imitation (or reproduction) of such protection currently does not cause any particular difficulties for manufacturers of counterfeit documents.

Fig. 49. Luminescence of special brands in UFL:

a — genuine; b, c — fake.

An example of this is the imitation of the luminescence of the background mesh paints on special stamps for marking alcoholic beverages.

Fig. 49 shows a comparison of fragments of genuine and counterfeit stamps, and the illustration shows differences in color and intensity of glow of paints and fibers.

INFRARED PROTECTION

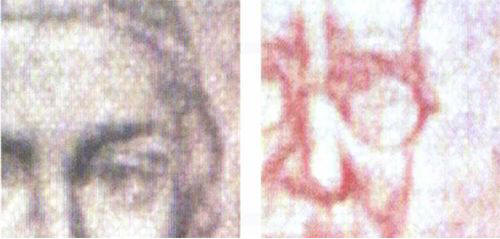

This type of protection is based on the properties of document materials (most often, coloring agents) to absorb or transmit infrared (IR) rays differently.

If, for example, there are a large number of devices available «in everyday life» to determine fluorescent protection, then special devices are needed to detect IR protection, usually used only by specialists. Therefore, such protection is usually classified as special. Although most reference publications do not indicate such features, they are still not a secret for specialists who can use both detectors and visualizers of infrared protection devices.

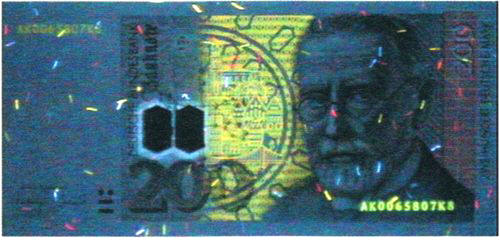

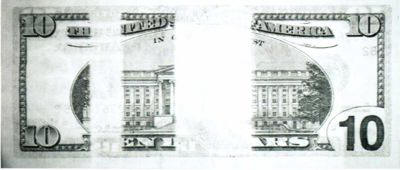

Currently, IR protection is also used in such common documents as banknotes. Even the US Federal Reserve System, despite its somewhat conservative nature, has begun to use this type of protection in its banknotes.

Thus, all US dollar banknotes, starting from 1999, contain an IR protection element in the image of the back side — a certain combination of transparent (invisible in infrared rays) vertical stripes (Fig. 50), and this combination is individual for each banknote denomination.

German stamps also contain the same type of protection, only here the localization pattern (sometimes also called IR contrast) is somewhat more complex (Fig. 51).

Fig. 50. IR absorption pattern

on the back of the 10-dollar US banknote.

Fig. 51. And this is what the absorption pattern looks like

in the IR range on a 200 German mark banknote.

In research practice, the term IR metameric paints is accepted. This is the name given to paints that look the same under normal conditions (under illumination and observation in the visible range of the spectrum), but differ in the nature of absorption in the infrared region.

Attempts to simulate infrared protection

It should be noted that earlier US dollar issues also contained infrared protection elements in the paints. Thus, the paints used to print serial numbers on $100 banknotes and the issuing bank designations were virtually indistinguishable in their IR absorption characteristics (Fig. 52a). At the same time, even serious counterfeits, such as the «super-96» class, can be easily distinguished from genuine banknotes by this characteristic (Fig. 52b).

Fig. 52. IR absorption of green paints on $100 banknotes:

a — genuine; b — counterfeit «super-96».

Naturally, reproducing (or imitating) infrared protection is quite a difficult task for counterfeiters. However, with the appropriate devices and reference books, a specialist can easily distinguish a counterfeit.

MAGNETIC PROTECTION

When talking about magnetic protection, we mean the presence of magnetic properties of the document materials. Most often, these are coloring agents, but sometimes the magnetic properties of security threads are used as protection.

Magnetic protection associated with coloring agents can be of two types. The first type assumes the presence of magnetic properties in some individual document attribute — usually this is a serial number. Most banknotes in circulation, some securities and other types of documents have this type of protection.

Magnetic protection of the second type assumes a local distribution of magnetic properties within the image. In this case, no external (visual) differences are observed. For example, black images on the front side of US dollar banknotes are provided with magnetic protection of this kind. If you study such an image using a special device (detector or visualizer), you can find that some areas of the image have magnetic properties, while others do not.

Imitation of magnetic protection

To simulate magnetic protection, various techniques are used, which are designed for the use of mainly simple devices (detectors). The first generation detectors were designed only to determine the presence of magnetic properties, but not their location. Therefore, it was quite easy to «fool» such devices — it was enough to produce a document using an electrophotographic device («xerox») or a laser printer, in which the coloring agent has magnetic properties. Or, on the areas of the image that should «be magnetic», a substance containing a ferromagnetic (for example, colorless paint with iron or nickel particles) was applied. In this case, the detector reacts to the presence of a ferromagnetic component in the coloring agent, but cannot determine the correctness of its location.

The methods of simulating magnetic protection in qualified counterfeits (class «super») have become more sophisticated. In this case, it is most likely worth talking not about imitation, but about reproduction of this type of protection. Thus, among the known counterfeits of US dollars belonging to this category, many reproduce the distribution of magnetic and non-magnetic sections (the so-called «magnetic image» of the banknotes) quite correctly. Nevertheless, almost all types of «super counterfeits» have some deviations from the genuine «magnetic image». It is difficult to judge whether this is done intentionally or not — but in practice, such differences can and should be used.

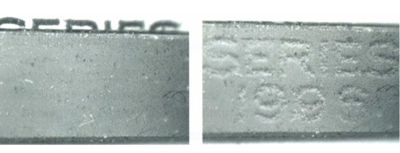

An example of such a difference is shown in Fig. 53. Here are fragments of the «magnetic image» of a genuine and counterfeit (class «super») banknote of 100 US dollars of the 1996 issue, recorded using a magneto-optical visualizer of the «MAG» type, equipped with a video camera. It is evident that in genuine banknotes the inscription «SERIES 1996» does not have magnetic properties, and in counterfeit ones — vice versa.

Fig. 53. Fragments of the «magnetic image» of the 100-dollar banknotes

issued in 1996:

a — genuine; b — counterfeit.

OTHER TYPES OF SECURITY

In addition to the listed types, so-called special marks can be attributed to physical and chemical protection. This term usually refers to the use of dyes with special properties, the detection of which is possible only with the help of special devices (detectors or visualizers). In reference and methodological literature, the terms «marks of type M», «marks of type I» are usually used. To detect these marks, various devices are used: both portable (wearable) and stationary (tabletop).

This type of protection is found, for example, in excise and special stamps on tobacco products and alcoholic beverages, as well as in some types of securities and other documents. Often (example — special stamps on alcoholic beverages) both elements of protection («M», «I») are combined in one graphic element.

A fairly large group is formed by means of document protection against copying. Moreover, these means are provided both by means of special printing technologies and by using materials with special optical properties (dyes, polymer films, etc.).

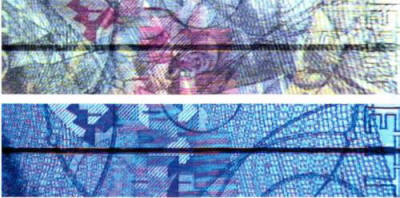

An example of the application of this type of protection is the use of metallic paints. Such paints («silver-like») are used to indicate the denomination on Russian ruble banknotes issued in 1997. Also, a special paint is used to overprint the denomination over the main image on German mark banknotes (Fig. 54).

These same illustrations show that another security element is located in this section of the banknote — a relief colorless image (the so-called REAC effect).

Fig. 54. Anti-copying features

on a 200 German mark banknote:

a — the relief image of the inscription

200 DM is clearly visible, and the overprint appears pale gray;

b — overprint in the form of a gold-colored strip.

PRINTING SECURITY

CLASSIC PRINTING: FEATURES OF THE MAIN PRINTING METHODS

LETTER PRINTING

FLAT PRINTING

INTEGRATED PRINTING

SCREEN PRINTING

SPECIAL TYPES OF PRINTING

MICROPRINTING Attempts to imitate microprinting

COMBINED IMAGES Imitation of combined images

HIDDEN IMAGES Attempts to imitate latent images

Imitation of printing security methods

Chapter 3

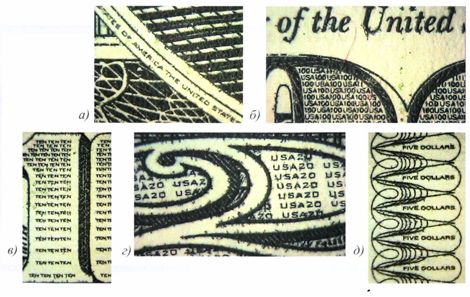

It is generally accepted that printing security means are a set of printing techniques and methods (printing technologies) that determine the properties of the image visible on the document.

When using these means, two types of features are formed in documents:

- the actual signs of printing methods. They are determined primarily visually, under normal conditions or with the help of simple devices, such as a magnifying glass;

- special effects indicating the use of a specific technology. Such features are usually detected by other methods (in oblique lighting, by touch, etc.).

In order to better understand how these features are displayed in documents, it is necessary to have a general idea of the printing methods. Here it is appropriate to immediately make a reservation: a detailed consideration of this issue requires a fairly deep knowledge of the field of printing. Therefore, further information on the «classical» printing methods will be provided in the required volume, and then their varieties, which have found application in the production of documents, will be considered in more detail.

CLASSICAL PRINTING: FEATURES OF THE MAIN PRINTING METHODS

Printing methods are usually distinguished by the geometric structure of the printing form — depending on how the printing and non-printing (non-printing) elements on the form are divided. In this case, the printing sections of the form that transfer the ink to the print are considered to be printing, and the rest (that do not transfer the ink) are non-printing.

Printing forms are often referred to by the general term «cliche». It should be borne in mind that in printing this term usually refers to illustrative forms of letterpress printing. In other literature, this concept is sometimes extended to forms for other methods.

According to this feature, it is customary to distinguish four main printing methods:

- high;

- deep;

- flat;

- screen.

Each of these methods has a number of varieties, some of which are usually used for printing so-called publishing products (books, newspapers, magazines), while others are used for the production of banknotes, securities, identity documents, as well as printing on products, packaging, etc.

Basically, these varieties differ from each other in the following parameters:

- the method of paint transfer — direct or indirect — is there an intermediate carrier, or transfer link, or is it absent;

- paint viscosity — thick (viscous) or liquid (low-viscosity);

- method of making a printing plate — mechanical or photomechanical (another term — photo-chemical, that is, using photographic and chemical processes);

- purpose (type of product) — publishing, packaging, printing on products, etc.

It should be noted that images obtained by printing methods can be conditionally divided into two types:

- line, which has only two gradations of tone — black (color) and white;

- halftone — having intermediate tones (densities).

The methods of changing the tone can be different, their description is given in the relevant sections.

LETTER PRINTING

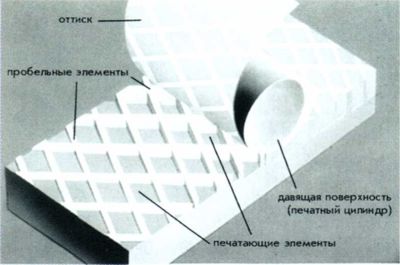

In letterpress printing (Fig. 55) the printing elements of the printing form are located above the non-printing ones. Therefore, when paint is applied to such a form, it covers only the printing elements. A typical example of a letterpress form is a rubber stamp.

The paint applied to the printing elements of the form is transferred under pressure to the receiving surface (in most cases, this is paper), on which an image is formed as a result — a print. At the same time, some amount of paint is forced out of the printing elements of the form due to the pressure, forming a thickened layer along the edges of the strokes on the print. Fig. 56 shows a schematic image of a print made using the letterpress printing method.

Fig. 55. Diagram of the letterpress printing process.

Fig. 56. Schematic representation

of a relief printing impression.

The extrusion of paint on the edges of the strokes is a feature inherent in all varieties of the relief printing method.

In addition, as a result of the pressure of the printing form, the receiving surface (paper) is deformed — a recessed relief is formed on the front side of the print, and a convex relief on the back. This feature is typical for prints made from solid printing forms using the direct method (without an intermediate carrier or, in other words, a transfer surface). This technology is usually meant when talking about «classical» letterpress printing; it is sometimes also called typographic printing.

The characteristic features of a letterpress print are shown in Fig. 57.

Fig. 57. Features of the impression of «classic» letterpress printing:

a — squeezing out paint on the edges of strokes on the front side;

b — convex relief on the back side.

The letterpress printing method also includes: flexographic printing (flexography) and typo-offset (high offset). These technologies are usually considered special printing methods.

Flexography— is a type of direct letterpress printing that uses flexible printing plates and low-viscosity inks. This method is used primarily for printing on packaging.

Offsetis an indirect method, where the printing form is a relief printing form, but the ink from it is first transferred to the intermediate surface (offset cylinder), and then to the substrate (paper or other material). Offset printing, or rather its special modifications, is used in the production of documents (see Special printing methods).

In the production of documents, relief printing is used mainly for applying variable details, such as serial numbers.

In cases where the number is applied directly to the substrate (paper), the impression is characterized by the features of «classic» relief printing — squeezing out the ink on the edges of the strokes on the front side (Fig. 58) and a convex relief on the back side.

Fig. 58.

If the number is applied over another image, for example, a background grid or the main drawing, the nature of the paint placement may be different. Thus, numbers printed over background grids made using offset or letterpress (Orlov) printing methods are characterized by almost the same features as “classic” letterpress printing (Fig. 59).

|

|

|

Fig. 59. |

Fig. 60. |

And if the image is made, for example, by the intaglio method, then the morphology of the number strokes changes significantly. Fig. 60 shows a case where the serial number is applied to the main image of the banknote (Estonian kroon), made by the intaglio method. Since the intaglio imprint has its own convex relief, the paint in the number strokes is applied unevenly, in accordance with these irregularities.

This combination of printing methods — high intaglio printing — is also found in the familiar US dollar banknotes. On them, the Treasury seal (green, on the right side) is printed using the high intaglio printing method, over the banknote denomination, which is printed using the intaglio printing method. The relief of the main image is large enough to prevent the green ink from penetrating the paper. Therefore, in most cases, the image of the Treasury seal on genuine dollars is characterized by incomplete printing of areas superimposed on the image of the numbers or letters indicating the denomination (Fig. 61).

Fig. 61.

FLAT PRINTING

A characteristic feature of flat printing is the absence of spatial separation of the printing and non-printing elements of the printing form.

In flat printing forms, the printing and non-printing elements differ not in height, but in their physical and chemical properties. During the manufacturing process, special treatment is carried out, as a result of which the printing elements acquire the ability to accept paint, and the non-printing elements — to repel it.

In the printing literature, the terms oleophilicity (hydrophobicity) and oleophobicity (hydrophilicity) are commonly used to describe the process of flat printing. The first two terms denote the ability of the printing elements to accept printing ink and repel water, the other two denote the ability of the non-printing elements to repel ink and accept water. To obtain these properties in flat printing, the surface of the printing plate must be moistened before applying the ink.

Depending on the material of the printing plate, its physical and chemical preparation, and the method of transferring the image, flat printing is usually divided into offset, lithographic, and phototype printing.

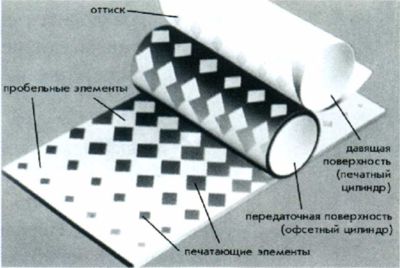

Usually, when talking about flat printing, offset printing is primarily meant.

Actually, the full name of this technology is flat offset printing. Here, the term “flat” refers to the geometry of the printing form, and “offset” refers to the method of transferring paint from the form to the receiving surface and implies the presence of an intermediate (transfer) link. Usually, this is a cylinder covered with rubber. It is called offset (from the English “to set off”) — it takes paint from the form and transfers it to the paper. In everyday life, the name “flat” is often omitted, calling this method simply offset printing.

Thus, offset printing is an indirect method of flat printing, the diagram of which is shown in Fig. 62.

Fig. 62. Diagram of the flat offset printing process.

Due to the uniform distribution of pressure over the surface of the form, offset prints are characterized by uniform coloring of the printing elements and clear contours, as well as the absence of paper deformation from the pressure of the form.

These features are demonstrated by the diagram in Fig. 63.

Offset printing is currently the most widely used method of printing reproduction.

It is used both for printing publishing products (books, newspapers, magazines) and for producing a wide variety of documents.

Fig. 63. Schematic representation of an offset print.

Fig. 64 shows a fragment of a “classic” offset print — this is the text in a book.

Fig. 64.

Lithographic printing (lithography) is historically the earliest method of flat printing. It was developed at the end of the 18th century. Special stones were used as printing forms, the surface of which acquired oleophilic and oleophobic properties after chemical treatment. This is a direct printing method.

Currently, lithography is used only for printing special (usually author's) art publications.

Phototype printing (phototype) is also considered a method of flat printing. This is a direct printing method in which the basis of the light-sensitive layer is gelatin.

Phototype is the only «classic» type of printing that allows halftones to be reproduced without the use of a raster. The technology for producing phototype printing plates is quite complex, and the printing process is unstable.

According to some estimates, this method is considered to be almost ideal for reproducing halftone images. However, phototype printing is currently used extremely rarely (reproductions of paintings, facsimile prints) precisely because of the instability of the printing process.

In documents — securities, banknotes and other types — offset printing is used primarily for printing background images: protective meshes, patterns, and, in some cases, for applying text and graphic details.

Figure 65 shows a fragment of a background image on a banknote (Kyrgyz som).

Figure 65.

INTEGRATED PRINTING

The intaglio printing method (Fig. 66) uses printing plates on which the printing elements are located lower than the non-printing elements. The paint applied to such a plate covers its entire surface. Therefore, before the transfer (printing) begins, the paint is scraped off the non-printing elements using some device — a flat knife (squeegee) or a roller.

Fig. 66. Intaglio printing process diagram.

It should be noted that intaglio printing is practically the only method where it is possible to obtain a paint layer of varying thickness. The figure shows that the printing elements of the form have different depths.

Speaking of intaglio printing, it should be borne in mind that its most common varieties have fundamental differences.

Doctor blade gravure printing (usually just called gravure printing) is the «classic» printing method and is usually used for large print runs (magazines, advertising materials, packaging). It is generally accepted that this method provides the best quality printing of halftone images.

In this method, low-viscosity ink is transferred directly from the cells of the printing plate to the material being printed (direct method). It should be noted that the technology for producing the printing plate in this case involves the use of a raster, that is, the entire surface of the plate — be it text or an illustration — is divided into raster elements (dots of the same size). This is reflected in the print, the diagram of which is shown in Fig. 67.

Fig. 67. Schematic representation

of a deep printing print.

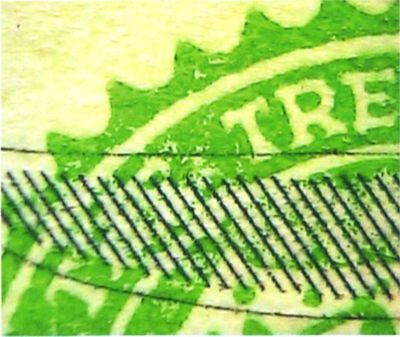

The appearance of a print made using the squeegee intaglio printing method is shown in Fig. 68. The illustration shows that the thin strokes of the print are broken down into practically separate dots, and in the wide strokes the raster structure is better visible at the edges in the form of “teeth” (sometimes referred to as a “sawtooth” structure).

In addition to squeegee, intaglio printing also includes metallography (metallographic printing) and pad printing (pad printing).

In intaglio printing, highly viscous printing ink is transferred from a printing plate made by engraving or etching directly to the material being printed (direct method).

Fig. 68. Features of the impression of «classic» (doctor) intaglio printing:

a — division of thin strokes, b — «teeth» on the edges of wide strokes.

Most often, impressions made by intaglio printing are line images (engravings).

Metallography is most often used for the production of banknotes, securities, and identity documents (see Special Printing Methods).

Pad printing is an indirect method of intaglio printing. When using this technology, an elastic pad (intermediate carrier) transfers paint from a metal (engraved or etched) or photopolymer printing form to the receiving surface.

Pad printing is used primarily for printing on various packaging materials or on items with unusual geometry (e.g. bottle caps, key buttons, souvenirs, etc.).

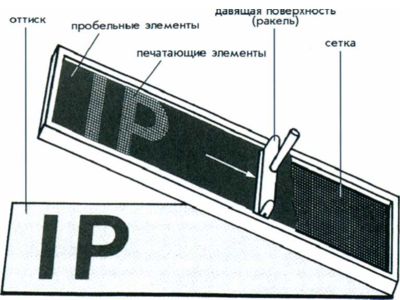

SCREEN PRINTING

The name of this method speaks for itself — the printing form here is a stencil. However, unlike the usual stencil in the form of a sheet of paper, cardboard, film with letters or a picture cut through them, the form of «classic» screen printing is a grid stretched over a frame. Printing and non-printing elements are formed on this grid in one way or another — the printing ones let the paint through to the paper, and the non-printing ones do not.

Thus, in screen printing, the paint gets to the substrate by pressing through the grid (Fig. 69).

Fig. 69. Screen printing process diagram.

This method of applying paint determines the type of prints obtained using screen printing — they always display the structure of the grid in one way or another (Fig. 70).

This method also has several varieties, however, of these, only silk-screen printing is used industrially.

Fig. 70. Schematic representation

of a screen printing print.

The term silk-screen printing reflects the history of this method — in the old days, screens were made from silk fabrics. In literature, you can also find the names ethnography and serigraphy — they all mean the same printing method. Most often, it is simply called screen printing.

Unlike other «classic» methods, screen printing can produce a very thick layer of paint (up to 100 microns), which determines the scope of its application.

The thickness of the paint layer depends to a large extent on the thickness of the threads, and the resolution of the process depends on the density of the mesh. Fig. 71 shows the type of prints obtained by screen printing from forms made on meshes of different densities.

Even in cases where there are no breaks in the lines in a screen-printed print, the grid structure is usually still visible in oblique light as a characteristic systematic relief on the surface of the ink layer (Fig. 72).

Screen printing is a very old method, however, nowadays it is used mainly for printing small runs in areas where a large thickness of the ink layer or saturation is required (labeling of products, posters, wallpaper production, as well as the field of artistic graphics).

Fig. 71. Fragments of screen printing prints:

a — with a coarse mesh (with large cells);

b — with a fine mesh (with small cells).

In addition, screen printing also includes rotary printing, a modern variety of which is risography. These technologies can be classified as office methods of document reproduction or, as they used to say, as operational printing.

Fig. 71.

Screen printing is practically not used for printing original documents, however, this method is quite often used (given the possibility of obtaining a thick paint layer) when imitating relief, typical, for example, for metallography.

SPECIAL TYPES OF PRINTING

As can be seen from the name, this group of printing technologies usually includes types of printing that have a special area of application.

At the same time, this group may include certain methods, depending on the classification basis: materials used, type and purpose of the product, the possibility of obtaining unusual effects, etc. However, all special types of printing have one property in common — these technologies are not used for printing standard or publishing products (books, magazines, newspapers, etc.). Although special types are variants of their «older brothers» — classical technologies, it is this characteristic that distinguishes them into a special group.

In this case, we will only talk about those special types of printing that are used in the production of documents — in the context of the subject under discussion. Therefore, the following technologies will be of interest to us:

-

Orlov printing;

-

offset printing;

-

metallography (including multi-color);

-

iris printing.

The first two types of printing are indirect methods of letterpress printing.

Orlov printing is a method of obtaining multi-color images from a single printing plate.

It is necessary to explain here that in classical printing (regardless of the printing method) the principle of multi-color image synthesis is used. According to this principle, all the required colors can be obtained using a limited number of colors — in most cases four, the so-called primary colors — cyan, magenta, yellow and black. Intermediate colors in this case are formed due to various combinations of the primary colors. In this case, to obtain a multi-color print, at least four printing plates are required (usually they are called color-separated). In this case, the application of paints to the substrate (paper) occurs sequentially, that is, each printing plate applies paint of one color.

In Orlov printing, all the paints are first applied to one printing form, and then they are all transferred to the paper at the same time.

Technically, this is a very complex process; such printing is only possible with special, unique and hard-to-find equipment. Since our task is not to study the technical subtleties of this process, it is only important to note the features that characterize it, which are discovered during the examination of documents.

Since the printing form is uniform, there are never any shifts of areas with different colors relative to each other in the impressions of the Orlov seal. At the same time, in places of transition from one color to another, when enlarged, one can see that the colors seem to mix, forming a small area of »transitional» coloring. In addition, being a type of letterpress printing, the Orlov seal has features inherent in this method, namely traces of paint squeezing out on the edges of the printing elements.

All these features are quite clearly visible in Fig. 73.

It should be said that modern document production also uses other technologies that allow obtaining a multi-color image from a single printing form. However, in them, the prints are applied not from relief printing forms, but from others — for example, from intaglio. In such cases, they sometimes talk about the «Orlov printing effect». Some of these technologies will be discussed below.

Fig. 73. This is what an imprint looks like when enlarged,

made using the Orlov printing method

(background grid on the pages of the passport of a citizen of the USSR).

Type offset, as the name suggests, combines two technologies: the printing form is a form of high (typographic) printing, and the image is transferred to paper through an intermediate carrier — the offset principle.

This combination determines the features revealed in documents produced by this method. On the one hand, the use of a relief printing form causes the ink to be squeezed out at the edges of the printing elements. On the other hand, the presence of an intermediate carrier, an offset cylinder, means that there is no deformation of the paper from the pressure (pressure) of the printing form.

Figure 74 illustrates the above features of a print made by the offset printing method.

Fig. 74. Typical type offset print

(fragment of the image on Russian ruble banknotes).

Sometimes in literature, type offset is called high offset, meaning a form of letterpress printing. The name dry offset is also encountered, that is, it does not require moistening, unlike flat offset printing. The latter term, however, is not entirely correct, since it usually refers to a different technology.

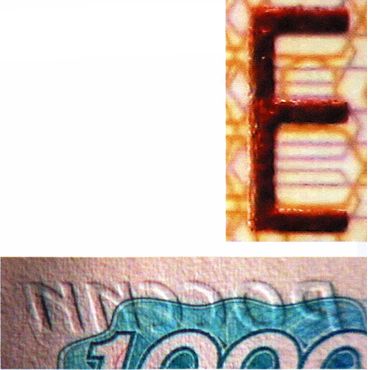

Intaglio printing is a type of direct intaglio printing, which is a recognized and one of the most powerful means of document printing security.

The printing form in intaglio printing is usually a line engraving made on metal (most often, copper or steel).

This technique is also called burin engraving. However, in industry, it is not the original engravings (made by hand by the engraver) that are usually used, but their galvanoplastic copies. The use of galvanoplastics allows obtaining practically identical copies of the original engravings, which allows the use of metallography for printing large editions of documents — banknotes, securities and other similar products.

In this case, the nature of the transfer of halftones in the image is fundamentally different from that used in «classic» squeegee intaglio printing. In metallography, images are usually line, not raster. Halftones are transferred here, firstly, by changing the width of the lines, and secondly, by varying the depth of the elements of the printing form and, accordingly, the thickness of the paint layer on the print.

In addition, in metallographic printing, very high pressure is required for normal transfer of viscous paint from the deep printing elements of the form to the paper.

For these reasons, in metallography prints, strokes are formed that are distinguished by a significant relief. On the one hand, the relief is due to high pressure (the stroke surface becomes convex even without paint), and on the other hand, a fairly thick layer of viscous paint is applied to this convex surface.

Fig. 75. Prints made by metallography:

a — convex relief on the front side;

b — concave on the back.

In addition, a concave relief is formed on the reverse side of the print due to the paper being pressed into the recessed elements of the printing form. Fig. 75 shows these features of metallographic prints.

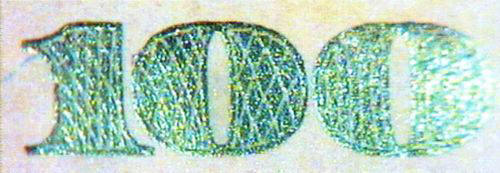

There are a number of other features inherent in intaglio printing. To retain the paint in the printing elements of the form, which have a large area, they are divided into smaller sections. In this case, the prints usually display a structure in the form of grids of varying density — «frequent» or «rare». Such are, for example, the structures of strokes in large inscriptions on US dollars (Fig. 76a) or in the design of travel coupons for Moscow city transport (Fig. 76b).

Fig. 76. The structure of strokes in prints made by intaglio printing:

a — in the inscriptions on US dollars;

b — in the design of travel coupons.

Multi-color intaglio printing is also used to produce documents. In this case, like the Orlov seal, all the colors are applied to the print from a single printing form. Therefore, in the prints one can observe, firstly, the features typical of intaglio printing (relief on the front and back), and secondly, the “Orlov seal effect”, i.e. the absence of displacements and breaks at the boundaries of areas of different colors. Only in the case of multi-color intaglio printing, the zones where the colors mix can be either very narrow (Fig. 77a) or quite wide (Fig. 77b).

Fig. 77. Change in color in the strokes of impressions made by multi-color metallography:

a — sharp transition (inscriptions on German stamps);

b — smooth (special stamps “Strong alcoholic drinks”).

Iris printing is not actually a printing method, but a special technology for applying several colors to one printing form (regardless of its type — high or flat). In this case, all the colors are also applied to the paper simultaneously, but their distribution over the surface of the form is carried out by the ink apparatus of the printing machine. As a result, the colors mix with each other, forming blurred multi-colored stripes. In this case, a smooth change in the color of the strokes (iris roll) can be observed on the prints. Single transitions are possible (Fig. 78a); there can also be reverse transitions, sometimes called counter roll (Fig. 78b).

Fig. 78. Smooth color change (iris printing, or iris rolling):

a — single transition (background grid on special stamps);

b — double transition, or counter rolling (background grid on Russian rubles).

OTHER METHODS OF PRINTING SECURITY

In addition to the features caused by the printing method itself, printing protection also includes the features of the so-called graphic protection, which are formed when using special technological methods and complex graphic elements. Some of them are discussed in the following sections.

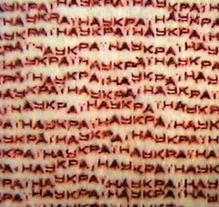

MICROPRINTING

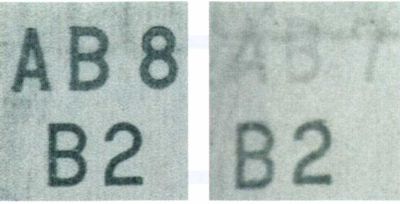

Microtexts are used as one of the most common means of graphic protection in documents — texts in which the size of characters is less than 0.4 mm (usually 0.2-0.4 mm). This element is produced mainly by metallography and offset printing (or typo-offset).

The content of microtext usually includes the name of the country, document and (or) issuer, denomination (in letters or numbers) and some other designations.

The range of microtexts is quite extensive. Most often, positive microtexts are encountered, that is, made with dark characters on a light background. An example is US dollars, where microtexts of this type are used in various forms: text lines in an oval frame (Fig. 79a), inside the denomination numerals (Fig. 79b, c, d), and also in guilloche frames (Fig. 79d). All these microtexts are made using metallographic printing.

Fig. 79 a, b, c, d, d. Positive microtexts on US dollars of various denominations.

Positive microtexts are also used to protect passport forms, for example, in the form of «corner» markings for photographs (Fig. 80), and in excise stamps — along the circumference of the coat of arms (Fig. 81). In the examples given, the microtexts are applied using offset printing.

Fig. 80. Positive microtext

on a USSR foreign passport.

Fig. 81. Positive microtext

on an excise stamp

«Tobacco products (RUSSIA)».

Fig. 82. Microtext in a negative image

on a banknote of 500 rubles of Russia.

In addition to positive ones, there are also microtexts made in a negative image (light signs on a dark background). They are sometimes also called reverse. An example of negative microtext is shown in Fig. 82.

All the microtexts shown above can be considered regular — all the characters in them have the same height and width of strokes. However, other types are also quite widely used — for example, with variable stroke thickness (Fig. 83) or character height (Fig. 84). Such microtexts are used as elements of document design and create various visual effects. On Ukrainian hryvnia banknotes, for example, the bends of the microtext lines form a pattern of larger digits — in Fig. 85, this is the digit «2».

Fig. 83. Variable stroke thickness of microtext

on the 100 German mark banknote.

Fig. 84. Variable character height

of microtext (excise stamps).

Fig. 85. Microtext forming the image

of the number «2» on the 2 hryvnia banknote.

Fig. 86. Transition from negative microtext

to positive on the 1000 Russian ruble banknote.

Combinations of styles such as a smooth transition from negative to positive are also used (Fig. 86). Sometimes the microtext is not located in any specific place (not locally), but is “scattered” over a large area of the document background, as on Danish kroner banknotes (Fig. 87).

Fig. 87. Microtext as an element of the banknote background.

Attempts to imitate microprinting

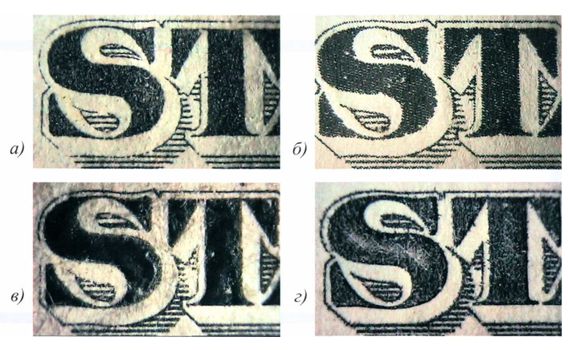

Microtexts in counterfeit documents are displayed with varying degrees of accuracy. In most cases, if we are talking about copying technologies (reprography) or simple printing processes, microtexts are reproduced with significant distortions.

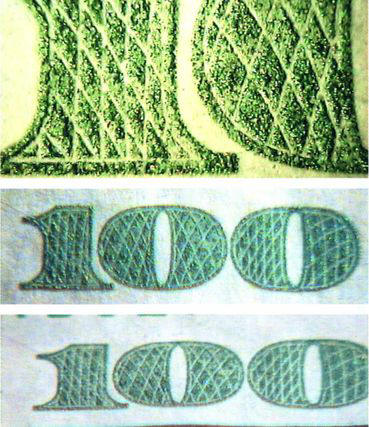

A fragment of a counterfeit banknote made using offset printing is shown in Fig. 88. Here, all the main black images on the front side are reproduced using a raster, and the microtext inside the numbers «100» was retouched (drawn) at the stage of making the photoform.

Another example illustrates a counterfeit when the microtext is quite well read, but even in this case we see that the text characters are still distorted (Fig. 89).

Fig. 88. Line microtext on a counterfeit

banknote made from a raster form.

Fig. 89. Distortion of microtext characters on a counterfeit banknote.

It is not common, but in practice there are also counterfeits where the microtext does not correspond at all in content to the original. The example in Fig. 90 illustrates a counterfeit excise stamp similar to that shown in Fig. 81.

Fig. 90.

COMBINED IMAGES

Another type of printing protection is considered to be combined images. There are two types of such images in documents.

The first is most common in single-page documents, especially banknotes. This type of combined images is usually called continuous. The reason for their name is clear from the illustration (Fig. 91). Due to the use of a special technology, the images at the edges of the banknotes are combined so precisely that they are, as it were, a continuation of each other — both in graphics and in color. This picture can be observed if you bend a banknote into a ring or combine the upper and lower edges of two identical banknotes.

Fig. 91. Continuous image on banknotes of the Bank of Russia

(10 rubles, 1997 issue).

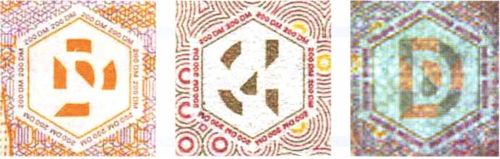

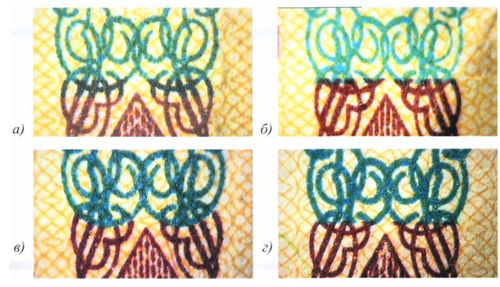

Combined images of another type — they are also called combination signs or illuminated registers — are observed when examining the document against the light. This type of protection is also based on the use of special technologies, thanks to which almost perfect combination of images of the front and back sides is achieved.

Typically, such images are a set of graphic elements, some of which are located on one side of the document, and some on the opposite side. A typical example of such protection is the combined images on German stamps. They contain fragments of the letter D placed in a hexagon (Fig. 92). When viewed against the light, these fragments complement each other, and a single image is formed.

Fig. 92. Combined image on banknotes of German stamps:

a — fragment on the front side; b — on the back; c — view against the light.

Imitation of combined images

Since simplified technological schemes are used in the vast majority of document forgery cases, it is quite rare to achieve good alignment of the images of the front and back sides. Often the discrepancy is about 1-2 mm.

Fig. 93. Combined image on a counterfeit

1000 German mark banknote (view through the light).

In some cases, however, quite good results are obtained, for example, as shown in Fig. 93. However, such an effect is more likely to occur with individual counterfeits or very small print runs. Mass counterfeits are unlikely to withstand any criticism.

HIDDEN IMAGES

This category of protection includes images created using special techniques that make it difficult to reproduce or imitate the original (genuine document). Mostly hidden images — sometimes called graphic traps — are intended to protect a document from copying, that is, reproduction by reprographic methods.

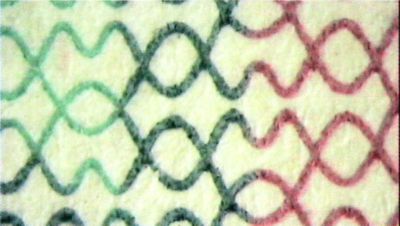

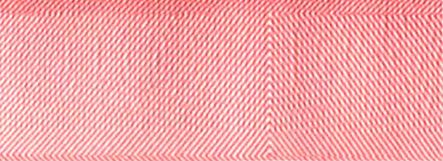

«Traps» are usually fragments of images with a regular structure — this can be a «classic» (dot) or linear raster (groups of lines of the same or different widths and directions). The combination of such elements forms a certain «hidden» pattern at the microscopic level. Externally (under normal examination), such areas look like uniformly colored areas of the background, and when magnified, their true structure is visible.

Examples of this kind of «traps» are shown in Fig. 94 and 95. The first case shows a fragment of a banknote (these are German stamps), where groups of parallel lines directed at different angles are applied.