Все про видеонаблюдение

Все про умный дом

Все о пожарной безопасности

Сейчас читают

Как ускорить и смотреть ютуб без тормозов и замедленияЕсли Вы на этой странице, то Вам, скорее всего, […]

Как ускорить и смотреть ютуб без тормозов и замедленияЕсли Вы на этой странице, то Вам, скорее всего, […] 10 лучших прогрессивных языков программирования для разработки мобильных приложенийЗнаете ли вы, что мобильные приложения — это не только […]

10 лучших прогрессивных языков программирования для разработки мобильных приложенийЗнаете ли вы, что мобильные приложения — это не только […] 6 важных особенностей, которые следует учитывать при строительстве нового домаСтроительство нового дома – это уникальная возможность […]

6 важных особенностей, которые следует учитывать при строительстве нового домаСтроительство нового дома – это уникальная возможность […]

Гороскоп на Сегодня

Automated ballistic identification systems — evolution in forensic technology.

ANCHUKOV Vladimir Aleksandrovich

DERENOVSKY Mikhail Efimovich, Candidate of Technical Sciences

Source: magazine «Special Equipment»

According to historians, forensic ballistics, which examines firearms used for illegal purposes, has existed for more than 175 years.

Identification features — unique traces left by the mechanics of weapons on spent cartridges and fired bullets — were largely studied by the beginning of the second decade of the 20th century.

On their basis, comparison methods were formulated.

And the invention of the comparative microscope in 1925 completed the creation of the technical basis for ballistic expertise, which has existed virtually unchanged to this day.

The rapid development of computer technology and microelectronics in the mid-80s, in particular, the emergence of powerful personal computers, high-capacity storage devices, corresponding software (SW), as well as sensitive CCD-based receivers, made it possible to begin developing automated ballistic identification systems in the early 90s.

With their appearance, the concept of creating electronic databases of images of the surfaces of fired bullets and spent cartridges acquired real outlines.

The practical use of automated ballistic complexes first abroad and then in Russia confirmed their obvious advantages, such as the speed of examination, the clarity of data, the possibility of remote access to stored information and others obtained when working with electronic bullet and cartridge case libraries.

Taking into account the huge number of ballistic examinations in connection with the growth of offenses involving the use of firearms, the emergence of new types of ammunition and weapons, and the expansion of their circulation, it is clear that conditions must be created for the widest possible use of such systems in the activities of law enforcement agencies of the Russian Federation.

The main technical problem that had to be solved when developing the complex was to create a device for recording digital images of the side surfaces of bullets and the bases of cartridge cases with the appropriate resolution and contrast in the computer memory, to obtain reproducibility of the image of the same object on different devices taking into account the features of the shadow image of the microrelief, to ensure the absence of information loss when recording images of deformed objects, etc.

This problem was solved with varying degrees of success by a number of developers, and in the mid-90s, the first automated ballistic identification systems appeared in Russia and abroad.

By the name automated ballistic identification complex (ABIC) we mean a functionally complete system, structurally consisting of three main parts:

- a scanning device for obtaining and entering a digital image of the objects of ballistic examination under study into the computer memory;

- a computer platform;

- Software that includes special software for controlling the scanning device and application software for working with the obtained digital images during ballistic examination.

The term “automated” in this case refers both to the scanning device and implies obtaining and entering an image of the entire side surface (or significant fragments) of the bullet and the base of the cartridge case in automatic mode, and to the software and implies the ability to automatically identify the image of the object being examined using the generated databases (DB).

From this point of view, the fairly common microscopes with television cameras as image receivers, providing one image frame, are not considered here due to the significant difference in the potential capabilities of microscopes and ABIC.

Obviously, the basic element of ABIC is the scanning device.

It is the scanning device and its design features that ensure the quality of the primary material — the digital image, and, ultimately, determine the effectiveness of the examination.

All known scanning devices contain functionally similar main units:

- unit for installing the object under study;

- unit of illumination;

- an optical unit that builds an image of the surface under study on the photodetector;

- a mechanical unit that ensures obtaining an image of any part of the object under study;

- a photodetector;

- a board for inputting images into a PC;

- control board for the executive mechanisms of the scanning device — motors, sensors, illuminators, etc.

However, functionally similar units differ in design, to varying degrees, taking into account the reasons affecting the quality of digital image recording.

Let's consider a number of such reasons.

Firstly, these are reasons of a natural nature.

The objects of the research – bullets and cartridges – are made of metal – a material with high reflectivity, i.e. the predominance of the coherent component over the diffuse one in the reflected light and a narrow range of gradation transmission in general in the resulting image.

This determines specific requirements for the illuminator.

It has been experimentally established that the best contrast at a given resolution is provided by a low-power diffuse source that eliminates glare and the formation of a speckle structure (for example, when using LEDs), having a narrow range of emitted frequencies in order to eliminate chromatic aberrations of the optical system.

Secondly, the subject of the research is the microrelief on the surface of objects, or more precisely, the shadow pattern formed by the microrelief under lateral illumination.

Therefore, in this case, the illumination should be as invariant as possible with respect to the position of the visible section of the object.

In other words, since the ABIK uses permanently installed illuminators, the shadow pattern must be reproducible on different copies of the scanning device and not depend (within acceptable limits) on the installation of the object.

Thirdly, bullets from crime scenes are often deformed, i.e. the surface being examined differs significantly from an ideal cylinder.

Therefore, the mechanical unit and the optical block must ensure that images of deformed objects are obtained with the same scale for effective examination.

Fourthly, a CCD matrix is used as an image, the parameters of which must be matched with the parameters of the optical system — magnification, relative aperture, depth of field — to obtain optimal resolution on the object.

It has been established that the optimal resolution is 3 — 4 µm.

With this resolution, the entire microrelief is displayed on the monitor screen and is not blurred by “noise” from the metal structure.

It should be noted that all known ABIKs use a black-and-white CCD camera as a receiver, despite the absence of fundamental difficulties in implementing the recording of objects in color images.

This is explained not so much by the significantly lower sensitivity and resolution of a color CCD camera compared to a black-and-white one, its higher price, the complexity of the optical scheme (when implementing an RGB camera), but by the significantly more effective comparison of black-and-white images both in “manual” and automatic modes.

Fifthly, the examined surfaces of the objects of examination are quite extended, their area is hundreds of square millimeters. This determines the design features of the mechanical unit for obtaining the entire (or a significant part) of the image of objects without loss of information, taking into account the high resolution.

Thus, a complex set of requirements is imposed on the ABIK scanner, the fulfillment of which is not achieved by all developers equally effectively.

Thus, some types of ABIK use separate scanners for obtaining and inputting images of bullets and cartridges.

In other cases, the scanner design is too complex or requires painstaking and lengthy preparatory operations when installing and recording the objects of study.

When identifying bullets and cartridges directly at the scene of the incident, the weight, dimensions, type of electrical power, ease of handling the objects and the equipment itself in the field, and similar factors are important.

These and other features of the scanners’ operation and design are reflected to a certain extent in the declared tactical and technical characteristics of the ABIK – maximum resolution, surface recording time, etc. (see Table 1).

Additional information for evaluating the equipment is provided by the comparison of recording methods used in various scanning devices below.

Let’s consider the most well-known ABIKs. They are represented on the market by products from Russian manufacturers:

- CONDOR complex (SDC, St. Petersburg), photo 1;

- TAIS complex (LDI-Ruspribor, St. Petersburg);

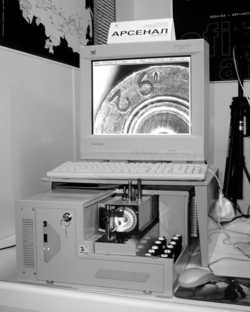

- Arsenal complex (Papillon Systems CJSC, Mias), photo 2;.

as well as foreign products:

- IBIS complex (Forensic Technology Inc., Canada), photo 3;

- Drug Fire complex (FBI, USA).

Photo 1. CONDOR complex by SDC

Photo 2. Automated system “Arsenal” of the enterprise “Papillon Systems”

Photo 3. IBIS complex of the company Forensic Technology Inc.

Since all manufacturers use the same computer platforms to varying degrees (usually personal computers such as IBM PC PENTIUM II and higher), the differences between the systems, their “pros” and “cons”, are mainly determined by the scanning devices and software.

Since the difference in cost between foreign and Russian systems is huge and, at the same time, judging by the available information and expert reviews, Russian ABIKs, not inferior to Western analogues in terms of basic technical indicators, have better service capabilities and are more convenient to operate, we will focus on reviewing the systems of Russian manufacturers.

In terms of equipment composition, some significant differences between the mentioned ABIKs deserve mentioning.

The CONDOR complex includes a universal optical-electronic scanning device (in a separate housing) with two types of removable cassettes (for bullets and cartridges), providing convenient and quick installation of the objects being examined in the scanner.

The image input device and the control and signal processing unit are installed in the computer.

The TAIS complex contains two separate optical-electronic scanning devices for recording bullets and cartridges, respectively, as well as two computers connected to each other in a network.

The complex includes two image input devices and two control and signal processing units, which are installed in each of the two computers.

The Arsenal complex contains a universal ballistic scanner on a linear CCD matrix for recording the surface of both bullets and cartridges (photo 4).

The number of expert workstations and data input stations is selected mainly based on the criterion of the database volume.

Photo 4. Ballistic scanner “Papillon BS” of the “Arsenal” complex

It should be noted that the network or multi-seat configuration of the ABIK complexes is not so much their qualitative difference as the implementation of specific user requirements.

The main problem here is to ensure compatibility of various complexes with each other at the upcoming stage of unification of local ballistic examination databases into a single information and analytical system of different levels.

Let's consider scanning devices in more detail.

First of all, they differ in the method of recording the surface being examined.

There are two main recording methods — “frame” and “slit” scanning.

In “frame” scanning, the surface being examined rotates around an axis (when recording a bullet) or shifts (when recording the base of a cartridge case) and is recorded in frames, the boundaries of which are “stitched” together according to a specific algorithm.

A CCD matrix is used as an image receiver.

In “slit” scanning, a very narrow area of the surface is recorded with each movement of the object – a line. A CCD array is used as an image receiver.

The “frame” scanning method has a number of fundamental advantages over “slit” scanning.

First of all, these are:

- higher quality of the resulting image due to more accurate approximation of the recorded surface by small areas — frames compared to narrow long strips — lines;

- higher speed of recording images due to significantly fewer mechanical movements during scanning;

- obtaining a single-scale image, since within one recording frame the scale is always the same and is determined by high-precision production of the pixel structure of the CCD matrix;

- the ability to preview the recorded frame of the surface of the object being studied, control the quality of the image recording and its machine analysis in real time, since each “current” frame can be displayed on the monitor screen;

- the ability to record both the full surface and fragments.

The device of the “Arsenal” complex uses the “slit” scanning method. The “TAIS” complex uses the “frame” scanning method. The “CONDOR” complex uses a modified “frame” scanning method.

The method is called “frame-fragment” recording and allows obtaining the fastest high-contrast image with the highest resolution.

The essence of the method is that the surface is recorded in frames, the image of which consists of the best-focused fragments.

It should be noted that foreign manufacturers also use CCD matrices as a receiver for recording the surfaces of objects under study.

In this case, scanning is not used when recording the base of the cartridge case (only one frame is remembered), and when recording the side surfaces of the bullets, “manual stitching” of frames and only fragments is performed, and not the entire surface.

In addition to the recording method, there are a number of design differences in scanning devices that determine the ease of use of the complex as a whole. First of all, this applies to the method of installing the objects being studied in the scanning device.

For example, in the Arsenal complex, bullets are glued and specially centered, while in the CONDOR complex, convenient removable holders are used, allowing the object of examination to be quickly installed in the scanning device without a lengthy centering procedure (installation time takes several seconds) due to the use of an effective automatic focusing system when recording each frame.

In the TAIS complex, unlike the CONDOR and Arsenal complexes, two separate scanning devices are used.

The weight and size characteristics of scanning devices and the supply voltage are also important. Reducing these characteristics helps to create mobile systems of this class.

Some comparative characteristics of known systems are presented in Table 1.

Table 1. Comparative characteristics of ballistic systems.

The issue of comparative evaluation of software is more complex.

Special software controls the operation of the scanning device and is determined by the recording method used and the design features of the scanning device.

Efficiently developed special software determines, all other things being equal, the speed and quality of recording images of objects being examined, as well as the service capabilities of the scanning device (for example, for the CONDOR complex, this is viewing objects in telemicroscope mode, changing the side of illumination of the object, “manual” focusing, and others).

The application software is designed to work with the received images and to one degree or another determines the efficiency of the complex for conducting ballistic identification expertise.

The application software can be divided into two parts: general and specific. The general part includes a set of capabilities that are mandatory declared by all developers.

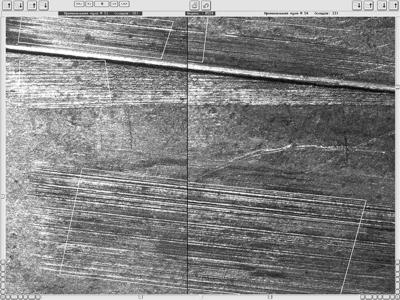

This is recording the received images in the database, storing, loading images from the database to the monitor screen for conducting a comparative examination in the so-called “manual” mode (similar to a comparative microscope).

The general part also includes the ability to search and identify objects by database, as declared by all manufacturers. However, the issue of automatic search requires special consideration and a number of considerations on this matter will be given below.

The specific aspects of application software include a set of functions that allow the most efficient work with images during “manual” examination.

These are functions such as image scaling, joint movement of images on the monitor screen, measurement of the ballistic parameters of the object (angle of inclination, width of rifling, etc.), quick transition from rifling to rifling, rotation of the image of the base of the cartridge case and many others.

Additional functions of application software, for example, the «CONDOR» complex are:

- function of correction of the angle of inclination of rifling, function of superimposing images on each other with a change in the «translucency» coefficient — «tracing paper» mode;

- function of displaying only primary traces on the screen or their combination with secondary traces and others.

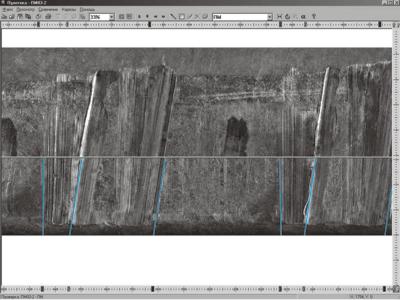

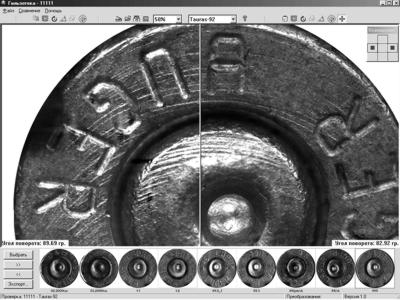

Examples of the screen interfaces of the CONDOR complex are shown in photo 5, and the Arsenal system – in photo 6.

Photo 5. Screen interface of the CONDOR complex

Photo 6a. Comparison of traces on bullets.

Photo 6b. Image of the bottom of the cartridge case and the measured surface profile.

In general, it can be considered that the software of all the presented complexes corresponds to their purpose and the accepted method of ballistic identification.

Now a few comments on the automation of search and identification by the database.

Seven years of experience in developing ballistic systems and studying a large number of objects — bullets and cartridges — allows us to make a cautious conclusion that to date, none of the manufacturers of systems have been able to obtain an acceptable formalism, expressed in obtaining a stable mathematical decision rule for automating ballistic examination for sufficiently large databases.

This is evidenced, for example, by information on the operation of the IBIS system, obtained both in Russia (the IBIS system is installed in the Forensic Science Center of the Ministry of Internal Affairs of the Russian Federation) and abroad.

The often cited analogy of ballistic examination with fingerprinting is very conditional due to the significant variability of traces on bullets and cartridges, compared to the papillary pattern.

In practice, we are talking about using correlation algorithms for the automated creation of a list of objects contained in a database, in descending order of their degree of similarity to a control object based on a set of specific characteristic features.

Today, it is generally recognized that the results of such an analysis are intended only to maximally facilitate and speed up the routine part of the expert's work, who in any case has to examine the selected objects and give his opinion on them.

Nevertheless, the issue of automation of ballistic examination of objects under study requires special attention due to the importance of the results of its solution and, consequently, the setting up and implementation of serious scientific research work.

The issue of the cost of the systems is also important. According to the results of a survey at the Interpolitex-2000 exhibition, the prices of systems from Russian manufacturers are approximately the same and fluctuate within the range of $15 — 25 thousand.

Considering that this price is quite high for Russian consumers, it is important to find ways to reduce it for the prospects of development and widespread use of ABIK.

Currently, the KONDOR-M complex has been prepared for release, which has almost all the characteristics and capabilities of the KONDOR complex, and is comparable in cost to the well-known MSK-1 microscope.

Despite all the differences in the understanding of the tasks of improving ABIK by various developers of complexes, there are problems that should unite them from the standpoint of common strategic goals.

Let us designate one of them — the construction of unified remote access networks and data exchange on the scale of individual regions and the country as a whole.

The solution to this problem should provide for the possibility of interaction of all ABIKs that meet a certain sufficient minimum of requirements that determine the necessary quality of bullet-proof archive data and the possibility of reliable comparison and identification of images of objects obtained using various complexes.

Active and fruitful development of ABIK in Russia provides objective prerequisites for the beginning of the reorganization of the technical base of ballistic expertise at a qualitatively new level.

An objective assessment of the achievements of all developers and the adoption of the best technical solutions as Russian standards for ballistic identification technology are necessary both for the establishment of healthy competition and for achieving the best results in the creation of effective technology.

Conclusions:

- An analysis of global experience and trends in the development of identification problems in general and forensic ballistics in particular allows us to draw an unambiguous conclusion that there is no alternative to ABIK in the near future.

Even today, existing developments significantly increase the efficiency of ballistic examination and provide the expert with wide opportunities due to the digital form of recording images of the objects under study.

In addition to conducting forensic ballistic examination, the high recording speed of the objects under study with high image quality will allow using ABIK in the creation of automated information retrieval systems for accounting for service firearms.

2. The issue of automating the ballistic examination of the objects under study requires coordination of the efforts of all developers, the formulation and implementation of serious research work in order to formulate recommendations for the development of algorithms for automating the identification of the object under study by the DB and the development of criteria for assessing the stability and reliability.

Добавить комментарий