Acoustic reconnaissance equipment: wired microphone systems and electronic stethoscopes.

KHOREV Anatoly Anatolyevich,

professor, doctor of technical sciences

ACOUSTIC RECONNAISSANCE MEANS:

WIRED MICROPHONE SYSTEMS AND ELECTRONIC STETHOSCOPES

Source: Magazine «Special Equipment and Communications»

Wired Microphone Systems

Acoustic reconnaissance equipment is actively used to intercept speech information from various premises. Acoustic reconnaissance equipment secretly installed directly in premises is especially widely used. Moreover, such equipment is installed not only in office premises, but even in residential apartments. For example, during special inspections of the residential complex of the USSR Embassy in Washington, numerous eavesdropping systems were discovered in most of the 183 apartments of employees of Soviet institutions in the USA [2, 3].

At the construction or major repair stage, miniature microphones can be covertly installed in the premises, the connecting lines of which are led out into the premises or even into other buildings located outside the controlled area, where the recording or transmitting equipment is installed. Such systems for intercepting acoustic information are often called wired microphone systems.

Wired systems mainly use electret microphones with a sensitivity of 20 — 60 mV/Pa, ensuring the recording of speech of average volume at a distance of up to 7-10 m from its source. In this case, the frequency range is from 20 — 100 Hz to 6 — 20 kHz.

As a rule, microphones are combined with preamplifiers. Two- or three-wire lines are used to transmit the information signal and power the amplifiers. DC voltage of 9 – 15 V is usually used to power the microphones.

The appearance of microphones with preamplifiers in a standard design is shown in photo 1, 2 [10, 11, 13].

Some microphone units, in addition to the preamplifier, have an electronic microphone on/off system (photo 3). If the conversation in the room stops, after a certain time set by the operator, the microphone is switched off. When an acoustic signal appears, the microphone switches on almost instantly (reaction time less than 1 s).

Photo 1. Microphones with standard-sized preamplifiers:

(frequency range 20 – 16000 Hz, signal-to-noise ratio 58 dB, dimensions 18x8x6 mm)

Photo 2. Miniature microphone with preamplifier MC-400

(frequency range 20 – 1000 Hz, signal/noise ratio 63 dB, dimensions 6x18x4 mm)

Photo 3. Microphone with preamplifier and electronic on/off system (the system shutdown time in the absence of an acoustic signal is adjustable — from 15 sec to 10 min; speech interception range — 5 m; microphone directional pattern — 100°; supply voltage 3 — 15 V)

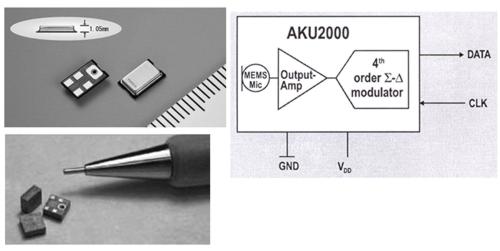

Development of new technologies, in particular MEMS technology(Micro Electro Mechanical Systems), led to the creation of fundamentally new digital MEMS microphones (sometimes called silicon microphones). Like a conventional electret microphone, a MEMS microphone consists of a flexible diaphragm, a rigid substrate, and a damping hole with an electric charge on the substrate. The diaphragm is in close proximity to the substrate, forming a capacitor. Under the influence of sound pressure, the diaphragm moves, changing the capacitance between it and the substrate. These changes are measured and output as an electrical signal. A MEMS microphone does not have a charge after manufacture. A charge at a voltage of 12 V is pumped into the substrate using a CMOS circuit. The chip maintains this charge when the microphone is activated [4, 7].

MEMS microphones are available both without an amplifier and with a built-in amplifier.

The microphone assembly (CMOS + MEMS) is placed in a housing on a metal board to create the Faraday cage effect. Filter capacitors are mounted on the substrate to protect against interference. The same housing contains a signal amplifier, various types of filters, and an analog-to-digital converter (ADC). The D-modulator is most often used as an ADC (Fig. 1) [9].

Fig. 1. External appearance of MEMS microphones in assembly (a),

structural diagram of MEMS microphone in assembly (b)

The MEMS microphone provides a uniform frequency response in the audio range from 100 Hz to 10 kHz and has a very high sensitivity, of the order of 42 to 26 dB relative (V/Pa), i.e. 8 to 50 mV/Pa [4, 7]. Thus, when used in wired systems of MEMS microphones in assembly (CMOS + MEMS), a digital pulse signal is transmitted to the line.

To improve the quality of intercepted conversations, microphones are usually installed near places where conversations may take place. To avoid detection, microphones are covertly installed in enclosing structures or camouflaged as interior items. Modern technologies make it possible to manufacture subminiature microphones that can be easily installed in a window frame or a picture frame. When properly installed in an enclosing structure (for example, in a building wall), a subminiature microphone is virtually impossible to detect even with a nonlinear locator.

The length of the connecting cable can range from 50-200 m to 5-10 km or more, such as in the PK-1055 SS system [8]. A relatively small reel can accommodate 50-100 m of cable (photo 4) [8].

Photo 4. Wired microphone system RK-900

(cable length 100 m)

To transmit information intercepted using microphones, in addition to specially laid cables, television cables, steam heating pipes, unused old 220 V network cables or connecting lines of security and fire alarm systems, etc. can be used. For example, microphones installed in various rooms of the USSR Embassy building in Washington, as well as one of the buildings in New York where Soviet citizens lived, were connected to transmit information to special water pipes used to transmit intercepted information and power the microphones. An ordinary metal pipe was covered with a special non-conductive material (insulation), then a conductive layer was applied, and its surface was again covered with insulation. Microphones were connected to a specially applied conductive layer and the metal of the pipe itself [1].

At the receiving point, the signal transmitted by the microphone is fed to a special low-frequency amplifier, and then recorded or transmitted via a communication channel to another receiving point.

The appearance of special low-frequency amplifiers is shown in photo 5, 6 [12, 13].

Photo 5. Special low-frequency amplifier

(frequency range 150 – 6000 Hz,

dimensions 113x37x75 mm; weight 0.3 kg)

Photo 6. Special low-frequency amplifiers of the series SIM—AULAS NT

(cable diameter 1.9 mm, maximum cable length 200 m)

Both single-channel and multi-channel systems can be used for listening to rooms. Examples of single-channel microphone systems include the PKI 2860 and PKI 2950 systems (photo 7, 8) [9].

Photo 7. Wired single-channel microphone system PKI2860

Photo 8. Wired single-channel microphone system PKI 2950:

a-special amplifier; b — cable reel

The PKI 2860 wired microphone system uses subminiature microphones with a frequency range of 250 to 3500 Hz. The transmission range is up to 500 m. The amplifier dimensions are 22x64x98 mm, weight 150 g. Power is supplied by a 9 V battery. Operating time is up to 50 h [9].

The PKI 2950 wired microphone system uses electret microphones with a frequency range of 100 Hz to 7 kHz (signal-to-noise ratio 60 dB/1 kHz). The reel with a 100 m long cable has dimensions of 180×60 mm and weight 600 g [9].

The receiving unit of the PKI 2950 system provides a maximum gain of 100 dB and has a built-in five-band equalizer (300, 600, 1200, 2400, 4800 Hz). The adjustment range is ± 10 dB. The unit has a headphone output of 4 — 16 Ohm and a linear output of 50 kOhm. The built-in 9 V battery provides an operating time of the unit of at least 20 hours. The unit weighs 750 g and measures 130x50x150 mm) [9].

A typical multi-channel system includes, for example, the SIM Rotel-30 wired microphone system (photo 9). The system is designed for listening to premises via a specially laid two-wire line. Up to 30 microphones can be connected to the line. The maximum cable length is 200 m. The receiving unit has dimensions of 225x200x70 mm. The unit is powered from an alternating current network AC 220 V [12].

Photo 9. Wired microphone system:

a – SIM Rotel1 (single channel);

b – SIM Rotel -30 (30-channel)

The SIM Rotel system uses electret microphones with built-in preamplifiers and control circuits. Each microphone is switched on by feeding an individual code signal into the line. The dimensions of the microphones are 9×25 mm. They are powered by a 12 V receiving unit. The microphone is powered by DC 12 V [2]. Microphones with preamplifiers contain semiconductor elements and can be detected using nonlinear locators.

To ensure secrecy for listening to premises, optical (fiber optic) microphones can be used, which do not contain semiconductor elements and, therefore, are not detected by nonlinear locators.

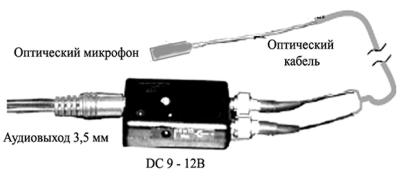

Such systems include, for example, the PKI 2960 system (photo 10, fig. 2) [9]. The optical (fiber-optic) microphone of the PKI 2960 system is designed to transmit acoustic information via a fiber-optic cable. The microphone is made in the form of a plastic cylindrical body with an end or side microphone input, has a double fiber-optic cable in a Teflon shell with optical connectors for connecting a signal processing device (photo 10). The frequency range of the microphone is from 250 to 4500 Hz. The microphone has a very high sensitivity from 0.3 to 1.8 V/Pa (table 1) [9].

Photo 10. Optical (fiber optic) microphone

Fig. 2. Signal processing device of the PKI 2960

The signal processing device is housed in a small plastic case with connectors for connecting an external power source, a recording device, and a fiber optic cable (Fig. 2). It has an emitting LED and a receiving photodiode. The emitted light signal is transmitted through one of the fiber optic cables to the sound membrane located in the microphone body. The reflected signal, modulated by the acoustic signal through another fiber optic cable, is transmitted to the receiving photodiode. Then the processing device isolates the acoustic component of the signal. The system is standardly available in 2 modifications, differing in the length of the fiber optic cable — 10 and 20 m.

Table 1. Technical characteristics of the optical (fiber optic) microphone PKI 2960

| Characteristic | Value |

| Directional pattern | omnidirectional |

| Frequency range, Hz | 250 – 4500 |

| Sensitivity, V/Pa | 0.3 – 1.8 |

| Signal-to-noise ratio (at 1 kHz), dB, not less than | 65 |

| Nonlinear distortion (at 84 dB signal level) | less than 1% |

| Maximum static pressure on membrane, dB, not less than | 130 |

| Supply voltage (DC), V | 9 –12 |

| Current consumption, mA, no more than | 80 |

| Microphone head weight, g | 1 |

| Microphone head dimensions, mm | |

| — diameter | 4.5 |

| — length | 21.5 |

Recording and transmitting equipment is installed in places where access is difficult. For example, in the building of the USSR Embassy in the USA, recording and transmitting equipment was installed in the rafters in the attic and in the foundation of the building at a depth of 2 m [2, 3]. Digital tape recorders and dictaphones with a long continuous recording time (from 60 to 300 hours or more) are mainly used as recording equipment.

For special processing of conversations recorded under conditions of various types of interference, equalizers are used, which are special devices with a set of various filters: high-pass and low-pass filters, bandpass, octave, Chebyshev and other filters. These filters are switched on according to a specific program depending on the nature of the signal distortion and interference.

Along with equalizers, special software and hardware speech noise cleaning systems are used to improve speech intelligibility, allowing noise and distortion to be eliminated. The following types of distortion are eliminated: vehicle noise, network interference, typical telephone network and radio channel interference, smooth music, household appliance noise (noise of a fan, vacuum cleaner, refrigerator, etc.), broadband and slowly changing noise, compensation for the uneven frequency response of a voice recorder, etc.

Needle microphones and electronic stethoscopes

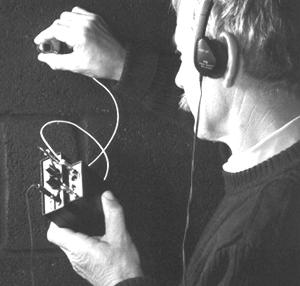

If there is access to rooms adjacent to the designated room, needle microphones and electronic stethoscopes can be used to listen to conversations.

Remote needle microphones are microphones with special thin sound guides (photo 11) and are designed to listen to conversations in adjacent rooms through natural or specially created gaps in the enclosing structures of the monitored rooms [9, 13].

For example, the PKI 2455 system uses an electret needle microphone with a sound guide diameter of 2.5 mm and a length of up to 300 mm. The conversation interception range is 10 m. The cable diameter is 2.5 mm. The system amplifier weighs 200 g and measures 95x60x25 mm (photo 12). The amplifier is powered by a 9 V battery. Battery life is up to 60 hours [9].

Electronic stethoscopes use contact microphones as sensors, which convert acoustic vibrations propagating in solids (walls, ceilings) into electrical ones.

Photo 11. Needle microphones:

a − PKI 2455;

b − XP-SP

Photo 12. Low-frequency amplifier of the PKI 2455

system

Electronic stethoscopes with contact-type sensors allow intercepting speech information without physical access of «agents» to designated areas. Their sensors are most often installed on the external surfaces of buildings, on window openings and frames, in adjacent (service and technical) rooms behind doorways, enclosing structures, on partitions, pipes of heating and water supply systems, air duct boxes of ventilation and other systems.

A typical contact microphone is a piezo accelerometer.[5, 6].

The seismic mass is attached to the base with an axial bolt, which presses the ring spring. A piezoelectric element is inserted between the mass and the base. When a force acts on it, an electric charge appears on its surfaces. There are many materials with such properties, but the most common is quartz. There are also synthetic ceramic piezoelectric materials that work quite well, even at higher temperatures than quartz allows. If the temperature of the piezoelectric element increases and reaches the so-called «Courier temperature», its piezoelectric properties are lost. In this case, the sensor is considered faulty and cannot be repaired.

When the accelerometer is moved up or down, a force is exerted on the seismic mass by the sensing element. This is the only force acting on the mass, so it is proportional to the acceleration of the latter, which coincides with the acceleration of the entire system. The mass, in turn, presses on the sensing element with an equal (and opposite) force. Since the charge and voltage on the piezoelectric element are directly proportional to the magnitude of this force, we will ultimately receive an electrical signal proportional to the acceleration at the output. Piezo accelerometers have extremely high linearity in amplitude, so they have a very large dynamic range. The lower limit of acceleration that they can perceive is determined only by the electrical noise of the electronics, and the higher levels are limited only by the destruction limit of the piezoelectric element itself. This range of permissible amplitudes can cover eight orders of magnitude, or 160 dB.

The frequency range of accelerometers is very wide and can extend for some models from very low frequencies to tens of kilohertz. The high frequency response is limited by the resonant frequency of the seismic mass — piezoelectric element system. Due to this resonance, the sensor will produce a very strong voltage peak in response to excitation at its natural frequency, which for the most common accelerometers is about 30 kHz. Typically, the working frequency range of an accelerometer is up to 1/3 of its natural resonant frequency, which is highly dependent on the mounting method, with screw or stud mounting being the best.

Accelerometers of the «ICP» type have a built-in micropreamplifier. Such accelerometers have a low-impedance output, are less susceptible to interference, and their sensitivity does not depend on the length of the cable. The sensitivity of modern contact microphones is from 50 to 100 μV/Pa, which makes it possible to listen to conversations through concrete and brick walls more than 100 cm thick, almost any doors, as well as window frames and utility lines.

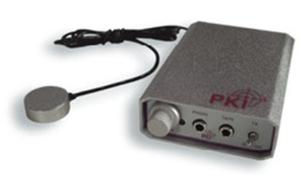

The appearance of some portable electronic stethoscopes is shown in photo 13 − 15 [9, 10, 12].

Photo 13. Compact electronic stethoscope complete with contact and needle microphones from Selavio

Photo 14. Compact electronic stethoscope PKI 2850

with contact microphone

Photo 15. Compact stethoscope SIM-STM-100

(frequency range from 10 to 15,000 Hz, gain 40 000;

power supply — 9 V battery, operating time up to 100 h, sensor dimensions 40-18 mm, sensor weight 80 g)

The PKI 2850 stethoscope is a typical representative of portable electronic stethoscopes. The dimensions of its amplifier unit are 95x60x25 mm, and the contact microphone is 50x35x15 mm. The gain of the stethoscope is at least 80 dB. The operating time from the built-in battery is up to 800 hours. Portable electronic stethoscopes use small contact microphones. For example, the SIM-STM-100 stethoscope uses a sensor measuring Æ40×18 mm and weighing 80 g.

Modern electronic stethoscopes have a gain of about 80 — 100 dB (10,000 — 100,000 times) and are capable of detecting weak sound vibrations (rustling, ticking of a clock, etc.). Foreign companies produce various types of stethoscopes, from the simplest portable compact ones to complex electronic stethoscopes equipped with a highly sensitive low-frequency amplifier and a set of built-in equalizer filters.

As an example, photo 16 shows the appearance of the professional electronic stethoscope PKI 2900, and its characteristics are in table. 2 [9].

Photo 16. Appearance of the professional electronic stethoscope PKI 2900

Table 2. Main characteristics of the professional electronic stethoscope PKI 2900

| Characteristic | Value |

| Maximum gain, dB |